CoilX: Difference between revisions

No edit summary |

|||

| (4 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

==Description== | ==Description== | ||

[[Image: | [[Image:CoilX_with_pigtails.jpg]] | ||

Getting a clean RPM signal on an engine is a tricky problem. The signal from the ignition coil is noisy, with multiple signal spikes reaching 400-500 volts. Directly tapping into this signal can cause erratic RPM readings at best, and at worse, damage electronic components. | Getting a clean RPM signal on an engine is a tricky problem. The signal from the ignition coil is noisy, with multiple signal spikes reaching 400-500 volts. Directly tapping into this signal can cause erratic RPM readings at best, and at worse, damage electronic components. | ||

| Line 13: | Line 13: | ||

==Wiring Information== | ==Wiring Information== | ||

* '''2 pin connector''' | |||

** Red: Coil Signal | |||

** Black: Ground (External) | |||

* '''3 pin connector''' | |||

** Yellow: 5v power | |||

** Black: Output | |||

** Red: Ground (data system) | |||

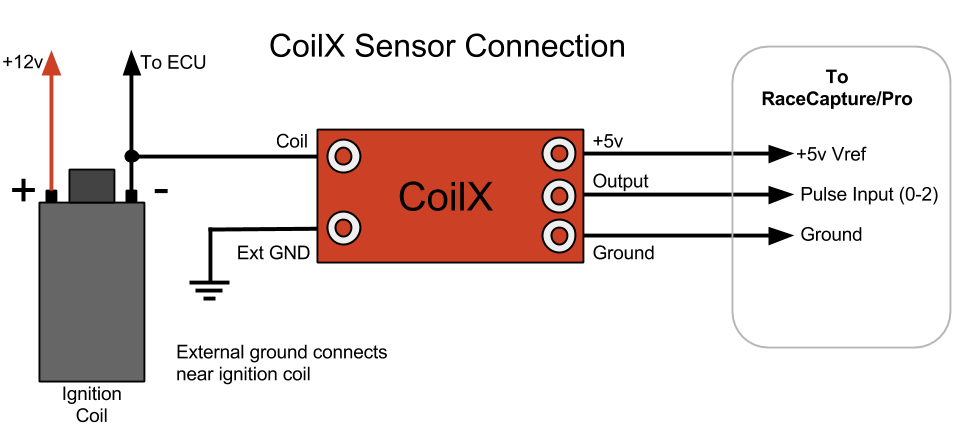

===Sensor Wiring=== | ===Sensor Wiring=== | ||

| Line 20: | Line 29: | ||

<center>[[Image:CoilX_sensor_connection.png]]</center> | <center>[[Image:CoilX_sensor_connection.png]]</center> | ||

==RaceCapture/Pro Connection== | ==RaceCapture/Pro Connection== | ||

* Connect the CoilX 5v connection to the 5v Vref connection of RaceCapture/Pro. | * Connect the '''CoilX 5v connection''' to the 5v Vref connection of RaceCapture/Pro. | ||

* Connect the CoilX | ** '''Do not exceed 5 volts or damage to module will occur''' | ||

* Connect the CoilX output signal to one of the Frequency / Pulse inputs channels. | * Connect the '''CoilX Data system ground''' connection to the same ground point as RaceCapture/Pro. | ||

* Connect the '''CoilX output''' signal to one of the Frequency / Pulse inputs channels. | |||

See the [[RaceCapturePro_installation_guide#Frequency.2FPulse_Input_1-3|Installation Guide]] for the full wiring diagram. | See the [[RaceCapturePro_installation_guide#Frequency.2FPulse_Input_1-3|Installation Guide]] for the full wiring diagram. | ||

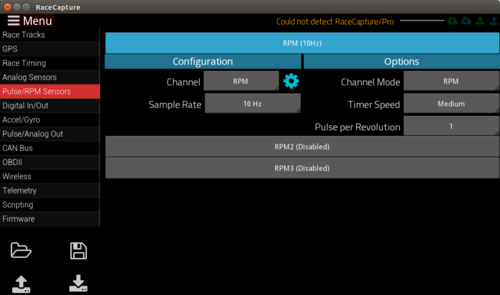

==RaceCapture/Pro Timer/Pulse Channel Configuration== | ==RaceCapture/Pro Timer/Pulse Channel Configuration== | ||

In the Race | In the Race Capture app, navigate to the [[RaceCapturePro_SoftwareOperation#Pulse_Inputs|pulse input channel configuration page]] and configure it for your settings. | ||

<center>[[Image: | <center>[[Image:rc_app_pulse_rpm_input.png|500px]]</center> | ||

* select RPM for channel Name | * select RPM for channel Name | ||

* select a sample rate. 10 to 20Hz is usually a good value to start with. | * select a sample rate. 10 to 20Hz is usually a good value to start with. | ||

| Line 49: | Line 48: | ||

'''PROTIP:''' With your engine running you can use the channel monitor to view the current live sensor data. | '''PROTIP:''' With your engine running you can use the channel monitor to view the current live sensor data. | ||

==Dealing with extra noisy signals== | |||

If you're still seeing an occasional high voltage spike, [[RaceCapturePro_Lua_Scripting_Examples#Simple_RPM_Filter|this script may help]] | |||

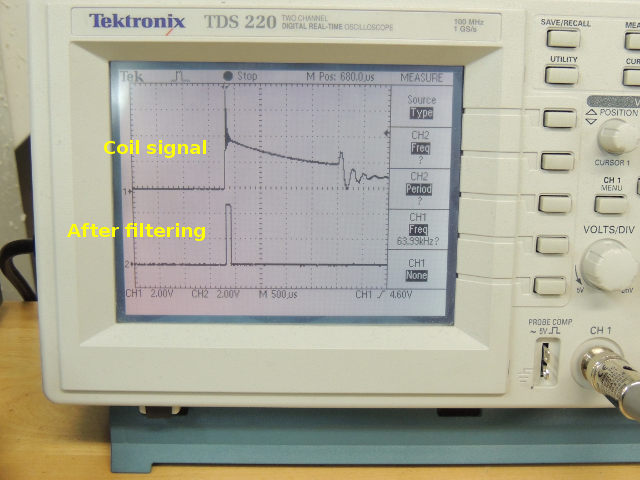

==Technical Information== | ==Technical Information== | ||

===Theory of Operation=== | ===Theory of Operation=== | ||

| Line 59: | Line 60: | ||

* The optoisolator output is further filtered through a single inverting logic gate using a [http://en.wikipedia.org/wiki/Schmitt_trigger schmitt trigger] filter. | * The optoisolator output is further filtered through a single inverting logic gate using a [http://en.wikipedia.org/wiki/Schmitt_trigger schmitt trigger] filter. | ||

* The filtered / conditioned 0-5v signal is fed into the RaceCapture/Pro timer input channel. | * The filtered / conditioned 0-5v signal is fed into the RaceCapture/Pro timer input channel. | ||

Latest revision as of 05:56, 30 January 2022

Description

Getting a clean RPM signal on an engine is a tricky problem. The signal from the ignition coil is noisy, with multiple signal spikes reaching 400-500 volts. Directly tapping into this signal can cause erratic RPM readings at best, and at worse, damage electronic components.

CoilX is a sensor module that converts the RPM signal from the ignition coil trigger wire into a clean 5v logic-level square wave that can be safely handled by the RaceCapture/Pro Timer / RPM input or other electronic devices.

The module features an optically isolated circuit with additional filtering, to help prevent false triggers.

The 1" x 0.5" compact board is designed to be assembled with heat shrink and bundled in-line with your wiring harness.

Wiring Information

- 2 pin connector

- Red: Coil Signal

- Black: Ground (External)

- 3 pin connector

- Yellow: 5v power

- Black: Output

- Red: Ground (data system)

Sensor Wiring

Connect the COIL signal from the CoilX module to the (-) connection of the ignition coil.

- If you have a multiple coil pack system, choose just one coil pack to connect.

- Alternatively, you may be able to tap into the tach signal going to your instrument cluster, but the signal here must be derived from the ignition coil. Newer vehicles (about 2000 and on) may have a low-level signal that may not work with CoilX. Consult your vehicle's documentation or measure the signal with an oscilloscope to verify.

RaceCapture/Pro Connection

- Connect the CoilX 5v connection to the 5v Vref connection of RaceCapture/Pro.

- Do not exceed 5 volts or damage to module will occur

- Connect the CoilX Data system ground connection to the same ground point as RaceCapture/Pro.

- Connect the CoilX output signal to one of the Frequency / Pulse inputs channels.

See the Installation Guide for the full wiring diagram.

RaceCapture/Pro Timer/Pulse Channel Configuration

In the Race Capture app, navigate to the pulse input channel configuration page and configure it for your settings.

- select RPM for channel Name

- select a sample rate. 10 to 20Hz is usually a good value to start with.

- Select Mode = RPM, Timer Speed = Medium, and pulse per revolution to match the number of cylinders.

- You may need to experiment with this setting to get the correct RPM reading.

PROTIP: With your engine running you can use the channel monitor to view the current live sensor data.

Dealing with extra noisy signals

If you're still seeing an occasional high voltage spike, this script may help

Technical Information

Theory of Operation

The CoilX module cleans and shapes the noisy 400v ignition flyback signal in the following way:

- The raw ignition signal is passed through a diode to prevent negative voltage transients.

- Then the signal is clipped via a Zener diode so voltages lower than 75v are discarded. This filters out the ringing components of the signal, which is the primary cause of false triggers.

- The clipped signal is passed through an optoisolator via current limiting resistors.

- The optoisolator output is further filtered through a single inverting logic gate using a schmitt trigger filter.

- The filtered / conditioned 0-5v signal is fed into the RaceCapture/Pro timer input channel.