BMW E36 Guide: Difference between revisions

(→Brakes) |

|||

| (12 intermediate revisions by 2 users not shown) | |||

| Line 17: | Line 17: | ||

* 4.64 volts at 100% | * 4.64 volts at 100% | ||

Configure a linear mapping in the analog input where the first bin is 0.62 volts / | Configure a linear mapping in the analog input where the first bin is 0.62 volts / 0 scaled value; 2nd bin is 4.64 volts / 100 scaled value. Repeat the 2nd bin values for bins 3, 4 and 5. | ||

==Engine Temperature== | ==Engine Temperature== | ||

''In research'' | ''In research'' | ||

Should be similar to [[BMW_E30_Guide# | Should be similar to [[BMW_E30_Guide#Engine_Temperature|E30]] | ||

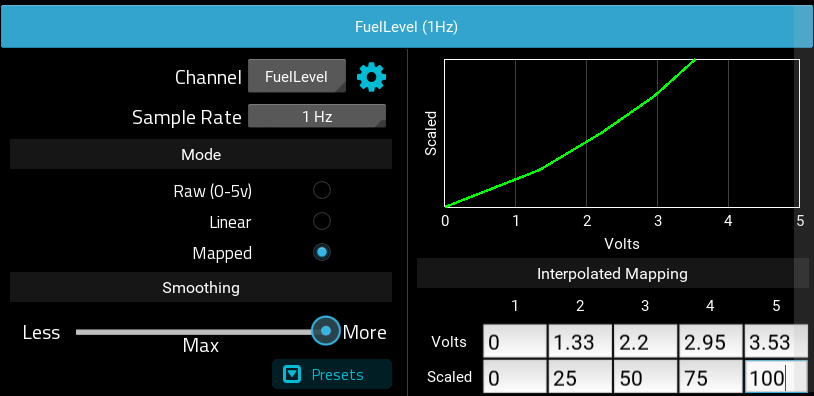

==Fuel Level== | ==Fuel Level== | ||

| Line 37: | Line 37: | ||

*3.53v = 100 (full) | *3.53v = 100 (full) | ||

[[file:BMW_E36_fuel_level_curve.png]] | |||

==Brakes== | |||

* | *Tap the Blue/Red wire coming out of the brake light switch on the back of the brake pedal. Wire this to a digital GPIO input of RaceCapture. Note: Must use a 10k Ohm resistor between the GPIO input and brake light wire. | ||

*Can be helpful to know when the driver actually applies the brakes for data analysis of the driver. This gives you a simple yes/no of whether the driver is on the brakes. Lets you know exactly when they applied the brakes. Use this in conjunction with TPS to see how much time they are 'coasting', or how long it takes them to transition from throttle to brakes and vice versa. | |||

* | |||

==Oil Pressure== | ==Oil Pressure== | ||

Recommend a dedicated 10 bar / 145 PSI 0.5-4.5v pressure sensor. [https://www.autosportlabs.com/product/10-bar-145-psi-fluid-pressure-sensor/ Pressure Sensor] | Recommend a dedicated 10 bar / 145 PSI 0.5-4.5v pressure sensor. [https://www.autosportlabs.com/product/10-bar-145-psi-fluid-pressure-sensor/ Pressure Sensor] | ||

==OBDII== | |||

You can get a few channels from the OBDII port of the E36 using the [https://www.autosportlabs.com/product/obdii-legacy-adapter/ ASL Legacy OBDII Cable], but it is fairly slow to update. Useful channels are RPM, EngineTemp, and TPS. See the [[RaceCapturePro2_OBD2|Enabling OBD-II Guide]]. It is also possible to [[RaceCapturePro_Lua_Scripting_Examples#Display_OBDII_Codes_as_a_channel_and_allow_driver_to_reset_the_OBDII_Codes_with_a_button|read and clear OBDII trouble/diagnostic codes via Lua Script]]. | |||

Available Sensors: | |||

*RPM | |||

*EngineTemp | |||

*TPS | |||

*IAT (needs to be converted to F) | |||

*WheelSpeed (needs to be converted to MPH) | |||

*MAF | |||

*EngineLoad | |||

*FuelFlowRate | |||

*Timing | |||

==Road speed (differential speed sensor based)== | ==Road speed (differential speed sensor based)== | ||

Latest revision as of 23:12, 29 June 2020

BMW E36 (1990 - 1999)

RPM

Use the wire connected to the instrument cluster #20, black wire. Also available on the round diagnostic connector at the back of the engine compartment (black wire, Pin #1)

RaceCapture/Pro Timer RPM Configuration

- Timer Mode: RPM

- Timer Speed: Medium

- Pulse Per Revolution: 3

TPS

Pin 2 (Black/Brown wire) of the Throttle Position Sensor is the voltage reference. Connect this wire to an analog input on your RaceCapture system.

Typical voltage values. You may need to measure this on your engine:

- 0.62 volts at 0% throttle

- 4.64 volts at 100%

Configure a linear mapping in the analog input where the first bin is 0.62 volts / 0 scaled value; 2nd bin is 4.64 volts / 100 scaled value. Repeat the 2nd bin values for bins 3, 4 and 5.

Engine Temperature

In research

Should be similar to E30

Fuel Level

Tap the brown/yellow wire that is in the small connector on the back of the dash closest to the driver's door.

Mapping in RCP

- 0.2v = 0 (empty)

- 1.33v = 25 (1/4)

- 2.2v = 50 (half)

- 2.95v = 75 (3/4)

- 3.53v = 100 (full)

Brakes

- Tap the Blue/Red wire coming out of the brake light switch on the back of the brake pedal. Wire this to a digital GPIO input of RaceCapture. Note: Must use a 10k Ohm resistor between the GPIO input and brake light wire.

- Can be helpful to know when the driver actually applies the brakes for data analysis of the driver. This gives you a simple yes/no of whether the driver is on the brakes. Lets you know exactly when they applied the brakes. Use this in conjunction with TPS to see how much time they are 'coasting', or how long it takes them to transition from throttle to brakes and vice versa.

Oil Pressure

Recommend a dedicated 10 bar / 145 PSI 0.5-4.5v pressure sensor. Pressure Sensor

OBDII

You can get a few channels from the OBDII port of the E36 using the ASL Legacy OBDII Cable, but it is fairly slow to update. Useful channels are RPM, EngineTemp, and TPS. See the Enabling OBD-II Guide. It is also possible to read and clear OBDII trouble/diagnostic codes via Lua Script.

Available Sensors:

- RPM

- EngineTemp

- TPS

- IAT (needs to be converted to F)

- WheelSpeed (needs to be converted to MPH)

- MAF

- EngineLoad

- FuelFlowRate

- Timing

Road speed (differential speed sensor based)

This calculates gear and speed based on the differential speed sensor.

Assumes:

- Engine RPM is connected to the first timer input.

- Differential speed pulse is connected to the 2nd timer input

The differential speed signal is on a black w/ white stripe wire and can be found in the following location:

- Pin 2 on connector X17 to the back of the gauge cluster

- Pin 10 on connector X22 on the cruise control module behind the glove box

- Pin 10 on radio connector

setTickRate(10) --10Hz

--virtual channels

--addChannel("name",SR,prec,min,max,"unit")

speeddiff_id = addChannel("Speed_",10,0,0,160,"MPH")

gear_id = addChannel("Gear_",5,0,0,5,"gear")

--global constants

--edit these to match your car

first = 4.20

second = 2.49

third = 1.66

fourth = 1.24

fifth = 1.00

final = 3.46

tirediameter = 24.7

--global variables

rpm = 0

rpm_diff = 0

speed = 0

function updateSpeedDiff()

rpm_diff = getTimerRpm(1)

speed = rpm_diff*tirediameter*0.002975

speed = speed + 0.5 -- round because 0 prec. truncates

setChannel(speeddiff_id, speed)

end

function updateGear()

rpm = getTimerRpm(0)

local gearErr = 0.15

local gear = 0

if speed > 2 then

ratio = rpm/(rpm_diff*final)

if ((first - ratio)^2) < (gearErr^2) then gear = 1 end

if ((second - ratio)^2) < (gearErr^2) then gear = 2 end

if ((third - ratio)^2) < (gearErr^2) then gear = 3 end

if ((fourth - ratio)^2) < (gearErr^2) then gear = 4 end

if ((fifth - ratio)^2) < (gearErr^2) then gear = 5 end

end

setChannel(gear_id, gear)

end

function onTick()

updateSpeedDiff()

updateGear()

end