MJLJ V3 vehicle installation guide

Crank trigger wheel and sensor installation

EDIS installation

EDIS and coil-pack installation

Since the EDIS module can operate the engine by itself in a "limp-home" mode, with the advance fixed at 10 degrees BTDC, it's recommended you install the EDIS module and coil packs first, and then verify your engine runs before wiring in the MJLJ.

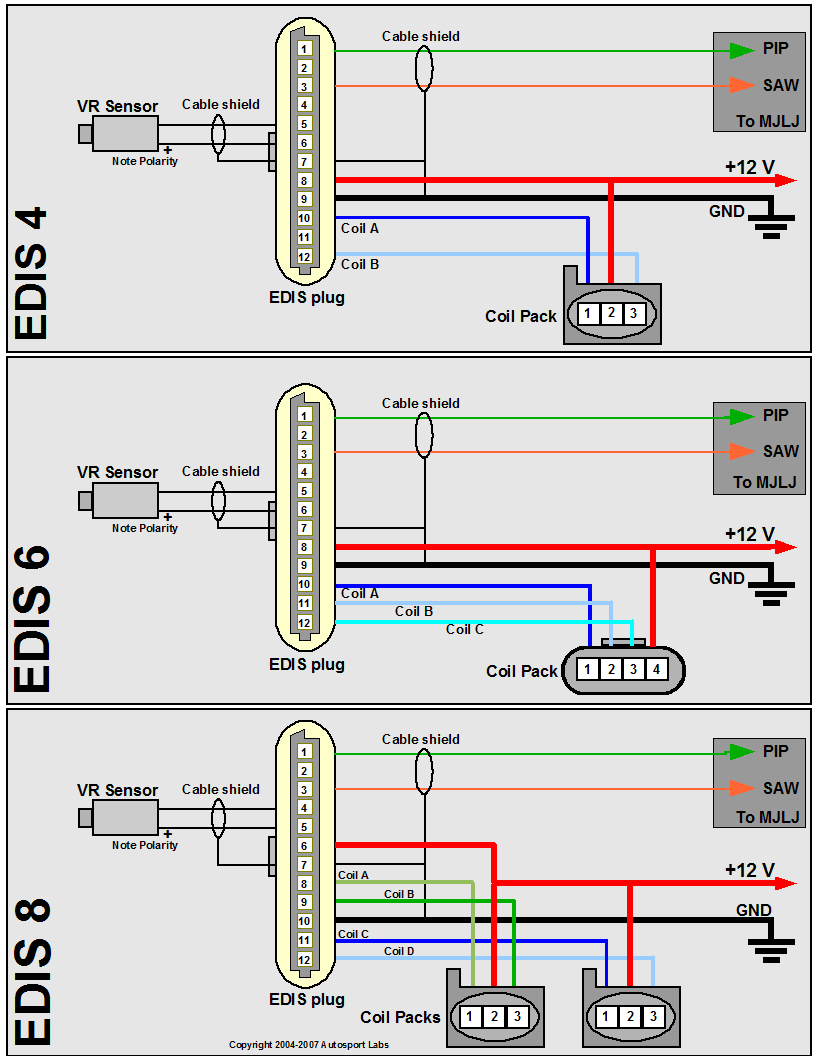

Wire up the EDIS module and coil pack(s) using the following diagram, matching your engine type (EDIS 4 = 4 cylinder, EDIS 6 = 6 cylinder, EDIS 8 = 8 cylinder). Engines with 'even-fire' configurations are supported, which represents the vast majority of 4,6, and 8 cylinder engines in production.

Wiring notes and guidelines

- Use shielded cable for the VR Sensor. Be sure to ground the shield as well. A 2 conductor cable with a foil shield works well.

- Note the VR sensor is polarized- you will not get spark from the EDIS module if it is wired backwards. If you don't see spark, reverse the connection on the VR sensor.

- Minimize supply voltage variances and especially ground loop problems:

- It's strongly recommended you power the EDIS module and MJLJ from the same electrical circuit. Typically this will be +12V switched (Key to "on" position)

- Ground both the EDIS and MJLJ at the same point on the chassis.

Installing the MJLJ

MJLJ wiring notes and guidlines

- The MJLJ should be installed inside the passenger compartment. It's not designed to handle the temperature,vibration and moisture extremes of the engine bay.

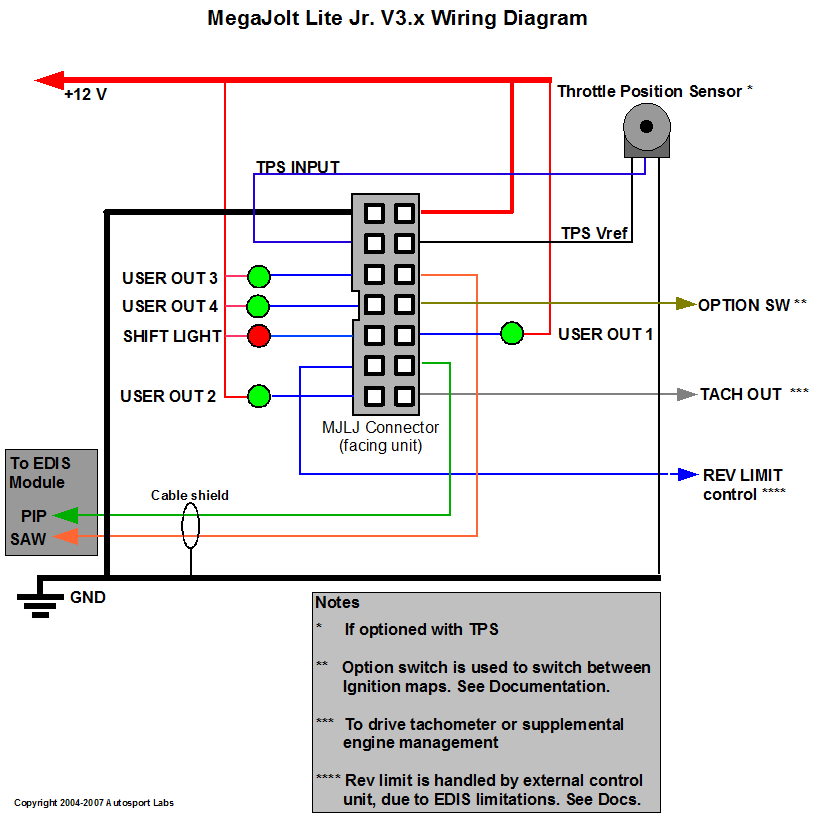

- Use shielded cable for the PIP/SAW signal between the MJLJ and EDSI module. Be sure to ground the shield as well.

- Use 16 gauge wire for the MJLJ ground connection, 18-20 gauge wiring is fine for the remainder of the connections.

- For MAP based setups ignore the TPS connections.

OEM tach adapter

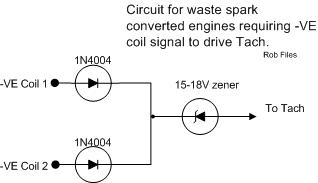

Many tachometers can accept the 12V signal emitted from the MJLJ module. however, some OEM tachs detect the RPM signal by sensing the high voltage flyback pulse from the ignition coil. In distributor based setups, there is only one ignition coil to detect this pulse from. With a wasted spark system like the Ford EDIS, you will have multiple coils providing this signal. Consequently you may need a way to detect this pulse across multiple coil-packs.

The following circuit allows the flyback pulse to be detected across individual coil packs while still isolating the coils from each other.