CAN Bus Integration: Difference between revisions

| Line 6: | Line 6: | ||

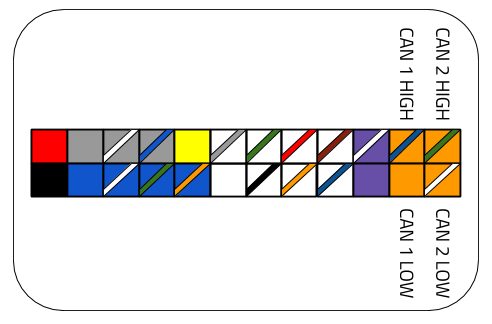

==Wiring CAN bus== | ==Wiring CAN bus== | ||

===Molex connector=== | |||

* Applies to | |||

** RaceCapture/Pro MK3 | |||

Both CAN ports are available on the molex connector: | |||

[[file:RaceCapture_Pro_MK3_Molex_CAN_pinout.png]] | |||

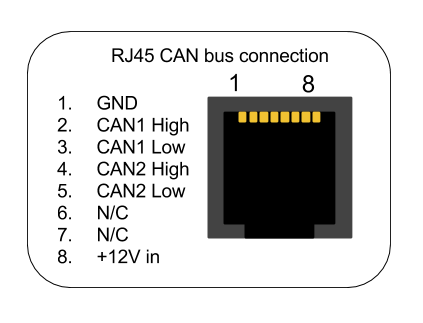

===RJ45 connector=== | |||

* Applies to | |||

** RaceCapture/Pro MK3 | |||

** RaceCapture/Pro MK2 | |||

This port is typically used for the optional CAN-OBDII interface cable, but can also be used for custom integrations. Both CAN channels are available on the RJ45 connection. | |||

====Cabling==== | |||

You can custom crimp an RJ45 cable, or you can use a standard CAT-5 ethernet cable with RJ45 connectors to integrate with RaceCapture/Pro. | |||

{| class="wikitable" style="text-align:center; width:700px; height:200px;" | {| class="wikitable" style="text-align:center; width:700px; height:200px;" | ||

|+ Power, ground and CAN bus connections to RaceCapture/Pro | |+ RJ45 Power, ground and CAN bus connections to RaceCapture/Pro | ||

|+ EIA-T568B RJ45 cable color codes (check printing on the cable to confirm) | |||

|- | |- | ||

! Connection | ! Connection | ||

| Line 27: | Line 45: | ||

|} | |} | ||

''' | [[File:RaceCapturePro_MK3_RJ45_pinout.png]] | ||

* '''Important note for MK2:''' The +12v connection on the RJ45 is connected internally to the +12v on the terminal block on RaceCapture/Pro MK2. It's recommended you only power via one source - RJ45 or terminal block - if you have both connected at the same time, you may cause back-feeding of power through RaceCapture/Pro, which may cause damage to the unit. '''Note: RaceCapture/Pro MK3 has internal protection diodes which avoids this issue.''' | |||

==Researching CAN Bus protocol== | ==Researching CAN Bus protocol== | ||

Revision as of 15:47, 14 April 2017

Introduction

Mapping an existing CAN bus system can be easy if documentation is available. ECU manufacturers are especially keen on providing documentation as they want their devices to easily connect to other systems, such as data systems and dashboards.

If documentation isn't available, the problem is just more interesting. Fortunately the CAN bus system is open in terms of it's messaging format and provides simple 8 byte message packets ident with a numeric identifier, much like an internet address, but a smaller number.

Wiring CAN bus

Molex connector

- Applies to

- RaceCapture/Pro MK3

Both CAN ports are available on the molex connector:

RJ45 connector

- Applies to

- RaceCapture/Pro MK3

- RaceCapture/Pro MK2

This port is typically used for the optional CAN-OBDII interface cable, but can also be used for custom integrations. Both CAN channels are available on the RJ45 connection.

Cabling

You can custom crimp an RJ45 cable, or you can use a standard CAT-5 ethernet cable with RJ45 connectors to integrate with RaceCapture/Pro.

| Connection | RaceCapture/Pro (RJ45 cable) |

|---|---|

| +12v | Brown |

| Ground | Orange/White |

| CAN 1 High | Orange |

| CAN 1 Low | Green/White |

- Important note for MK2: The +12v connection on the RJ45 is connected internally to the +12v on the terminal block on RaceCapture/Pro MK2. It's recommended you only power via one source - RJ45 or terminal block - if you have both connected at the same time, you may cause back-feeding of power through RaceCapture/Pro, which may cause damage to the unit. Note: RaceCapture/Pro MK3 has internal protection diodes which avoids this issue.

Researching CAN Bus protocol

If you are working to integrate an ECU, first ask the manufacturer for their CAN bus specification. This documentation will provide a breakdown of channels - such as RPM, temperatures and pressures and describe how they appear in the CAN message stream. A good example is the Megasquirt CAN Broadcast Specification

CAN Bus documentation

This document will show for each channel the following information:

- Channel: (RPM, Engine Temperature, Throttle Position, etc)

- CAN Identifier: The CAN Identifier for each channel. This may appear in either 11 or the extended 29 bit format. Typically 11 bits are used.

- Offset: where the data starts within the 8 byte CAN message. An offset of 0 means the data starts on the first byte.

- Length: Typically 1 or two bytes

- Scaling: The raw value from the message is often scaled to a real world value. Typically this is provided as a multiplier and adder value.

MSB or LSB mode

Additionally, the manufacturer will specify if multi-byte (16, 24 or 32 bit) values are presented in MSB (Most Significant Bit) or LSB (Least Significant Bit) mode.

MSB mode data will have the high byte presented first in the data packet and is typically the most common format.

Example:

- Decimal value: 1000

- Hex Value in MSB: 0x03E8

- Hex Value in LSB: 0xE803

If provided in a CAN message, it might show up as follows in this hypothetical message:

MSB format:

- Offset 1

- Length 2

- Data:

(Hex) [xx] [03] [E8] [xx] [xx] [xx] [xx] [xx] (Decimal) [xx] [3] [232] [xx] [xx] [xx] [xx] [xx]

LSB format:

- Offset 1

- Length 2

- Data:

(Hex) [xx] [E8] [03] [xx] [xx] [xx] [xx] [xx] (Decimal) [xx] [232] [3] [xx] [xx] [xx] [xx] [xx]

Reverse Engineering

Reverse engineering can be a rewarding experience, providing you can log the CAN data stream from the device and compare it against direct measurements on the system.

Common Approach

- Log all messages from the CAN bus

- Directly measure or observe a sensor channel and compare it against changes in the CAN bus data, watching for patterns.

Example

An example for decoding RPM: To detect which CAN message contains RPM, log all CAN messages while simultaneously directly logging RPM, synchronizing the messages and the direct RPM measurement in time. Watch for patterns in the CAN data: any data changing in sync with the direct RPM measurements will be a strong indicator of which CAN message contains RPM data.

Repeat with other sensors of interest, such as steering angle, tempertures, etc.

Logging Data

You can use a commercial CAN data logger, or simply use RaceCapture/Pro's CAN bus logger script to output all messages to the logging window.

Mapping CAN data to Virtual Channels

Connecting CAN bus data to a virtual channel is accomplished using the Lua scripting features of RaceCapture/Pro. The script allows you to define powerful custom behaviors for the system without having to crack open and modify the firmware.

Reading a CAN message

You can use the Lua scripting to read and process data from a CAN message. See the Lua Scripting reference for a list of CAN bus functions.

Example reading and printing the ID and first byte of a CAN message:

id, ext, data = rxCAN(0, 100)

print("ID: " ..id .."Data: " ..data[1])

Mapping to a Virtual Channel

You can create a virtual channel by using the addChannel() lua function. The typical approach involves:

- Set up the channel. Example "EngineTemp"

- Read a CAN message

- Extract a value from the data fields

- Scale the extracted value to a real world value (Example: Degrees F)

- Set the virtual channel with the scaled value

- Example: Set MyChannel from CAN ID 1234. Data is in the first byte of the message.

channelId = addChannel("MyChannel", 10)

setTickRate(10)

function onTick()

id, ext, data = rxCAN(0)

if id == 1234 then

setChannel(channelId, data[1])

end

end

CAN integration framework

Below is a script framework to ease mapping of CAN bus data to virtual channels. You can copy the script and modify as you need. This example showcases mapping some of the BMW E46 CAN bus channels.

To create your own integration, edit the top portion of the file to match your system's CAN bus configuration and data mapping.

--This example configured for E46 CAN

--how frequently we poll for CAN messages

tickRate = 30

--the CAN baud rate

CAN_baud = 500000

--CAN channel to listen on. 0=first CAN channel, 1=second

CAN_chan = 0

--1 for Big Endian (MSB) mode; 0 for Little Endian mode (LSB)

be_mode = 0

--add your virtual channels here

tpsId = addChannel("TPS", 10, 0, 0, 100, "%")

tempId = addChannel("EngineTemp", 1, 0, 0, 200, 'C')

oilTempId = addChannel("OilTemp", 1, 0, 0, 200, 'C')

rpmId = addChannel("RPM", 10, 0, 0, 10000)

--customize here for CAN channel mapping

--format is: [CAN Id] = function(data) map_chan(<channel id>, data, <CAN offset>, <CAN length>, <multiplier>, <adder>)

CAN_map = {

[809] = function(data) map_chan(tpsId, data, 6, 1 , 0.392156863, 0) map_chan_le(tempId, data, 2, 1 , 0.75, -48.373) end,

[1349] = function(data) map_chan(oilTempId, data, 5, 1, 1, -48.373) end,

[790] = function(data) map_chan(rpmId, data, 3, 2, 0.15625, 0) end

}

function onTick()

processCAN(CAN_chan)

end

--===========do not edit below===========

function processCAN(chan)

repeat

local id, e, data = rxCAN(chan)

if id ~= nil then

local map = CAN_map[id]

if map ~= nil then

map(data)

end

end

until id == nil

end

--Map CAN channel, little endian format

function map_chan_le(cid, data, offset, len, mult, add)

offset = offset + 1

local value = 0

local shift = 1

while len > 0 do

value = value + (data[offset] * shift)

shift = shift * 256

offset = offset + 1

len = len - 1

end

setChannel(cid, (value * mult) + add)

end

--Map CAN channel, big endian format

function map_chan_be(cid, data, offset, len, mult, add)

offset = offset + 1

local value = 0

while len > 0 do

value = (value * 256) + data[offset]

offset = offset + 1

len = len - 1

end

setChannel(cid, (value * mult) + add)

end

map_chan = (be_mode == 1) and map_chan_be or map_chan_le

initCAN(CAN_chan, CAN_baud)

setTickRate(tickRate)