ShiftX3: Difference between revisions

No edit summary |

|||

| (34 intermediate revisions by 2 users not shown) | |||

| Line 2: | Line 2: | ||

==Parts in the Kit== | ==Parts in the Kit== | ||

* ShiftX3 | * ShiftX3 | ||

[[image:shiftx3_3quarter.jpg|1024px]] | [[image:shiftx3_3quarter.jpg|1024px]] | ||

==Compatibility== | ==Compatibility== | ||

ShiftX3 is compatible with: | ShiftX3 is compatible with: | ||

* RaceCapture/Track MK2 | * RaceCapture/Track MK2,MK3 | ||

* RaceCapture/Pro MK2 | * RaceCapture/Pro MK2,MK3,MK4 | ||

* RaceCapture/Apex | * RaceCapture/Apex | ||

* PodiumConnect | * PodiumConnect MK1,MK2 | ||

'''Note:''' Not compatible with RaceCapture/Track MK1. | '''Note:''' Not compatible with RaceCapture/Track MK1. | ||

| Line 29: | Line 18: | ||

ShiftX3 requires RaceCapture/PodiumConnect firmware 2.15.0 or higher. [http://podium.live/software Download the latest firmware] | ShiftX3 requires RaceCapture/PodiumConnect firmware 2.15.0 or higher. [http://podium.live/software Download the latest firmware] | ||

=Connection and Installation= | |||

==Mounting ShiftX3== | ==Mounting ShiftX3== | ||

Attach ShiftX3 with #6 mounting screws and tighten until snug. | Attach ShiftX3 with #6 mounting screws and tighten until snug. | ||

* '''Note''': You can install with the 7 segment display above or below the LED strip; see the setup instructions for selecting the orientation. | |||

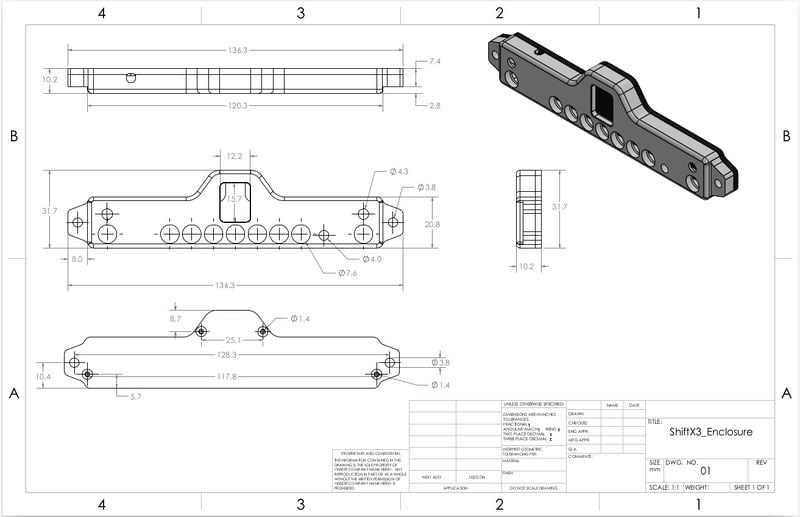

==Dimensions== | |||

* ShiftX3 with enclosure 136 x 32 x 9.46 mm (5.35 x 1.26 x .37 inches) | |||

* Enclosure DXF and PDF drawing [[file:ShiftX3_enclosure.zip]] | |||

[[image:ShiftX3_enclosure_dimensions.jpg|800px]] | |||

===Plug and Play connection=== | |||

* '''Note:''' ShiftX3 requires 12v power, via RaceCapture's own power connection. | |||

ShiftX3 connects effortlessly into our plug and play connector system, using the recommended cabling accessories: | |||

[[ | * [https://www.autosportlabs.com/product/can1-can2-dual-can-splitter/ Dual CAN splitter] | ||

* [https://www.autosportlabs.com/product/can-bus-extension-cable/ CAN extension] (choose your desired length) | |||

* [https://www.autosportlabs.com/product/inline-can-terminator/ Inline CAN terminator] | |||

Connect the Dual CAN splitter into the CAN1/CAN2 port of your main system: | |||

[[file:dual_can_splitter_plugged_in.jpg|600px]] | |||

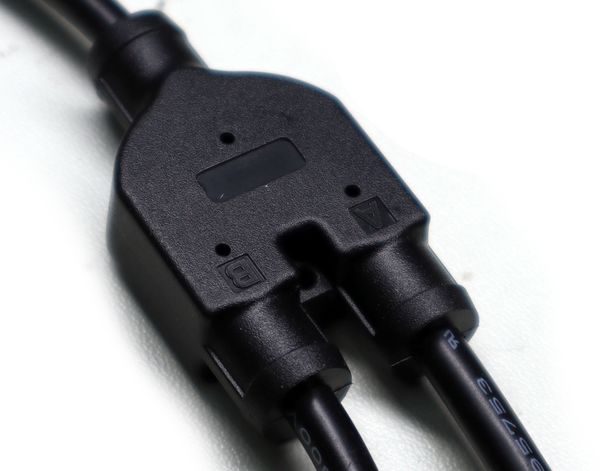

Then connect your CAN extension cable to the "B" port of the Dual CAN splitter: | |||

[[file:dual_CAN_splitter_closeup.jpg|600px]] | |||

At the opposite end of the CAN extension, attach the inline CAN terminator: | |||

[[file: | [[file:inline_terminator_plugged_in.jpg|600px]] | ||

Finally, attach ShiftX3 to the other end of the Terminator to complete the installation. | |||

[[file:ShiftX3_with_terminator.jpg|600px]] | |||

===Direct wire connection=== | |||

You can connect ShiftX3 into a non plug and play system by using the following cabling accessories: | |||

[[ | * [https://www.autosportlabs.com/product/can-power-pigtail-for-device/ Device Power+CAN Pigtail] | ||

* [https://www.autosportlabs.com/product/inline-can-terminator/ Inline CAN terminator] | |||

Connect the pigtail wires to your system: | |||

* Green to CAN2 High | |||

* White to CAN2 Low | |||

* Red to +12v (same power connection for your system) | |||

* Black to Ground (same ground connection for your system) | |||

Then connect the pigtail to the inline CAN terminator. | |||

Finally, attach ShiftX3 to the other end of the Terminator to complete the installation. | |||

=Using ShiftX3= | |||

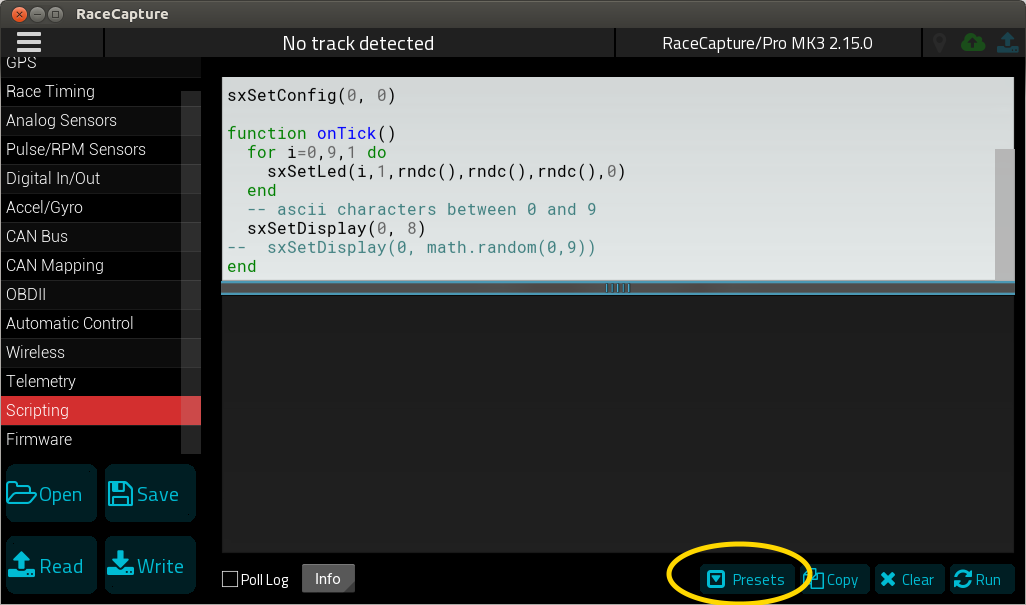

The LEDs and display on ShiftX3 are controlled by RaceCapture's Lua scripting capabilities. Built-in functions provide access to ShiftX3's capabilities. See the [[RaceCapturePro_Lua_Scripting#ShiftX2.2F3_control|ShiftX3 Lua scripting reference]] for additional details. | |||

'''Note:''' Ready to go scripts may be available as a preset. When in the Scripting view, press the Presets button to access a list of pre-configured scripts. Be sure to press the cloud update button to get the latest set of presets. | |||

[[image:Lua_scripting_presets.png]] | |||

| | |||

'''Note:''' | |||

=ShiftX3 | ==Navigation Buttons== | ||

Once ShiftX3 is powered and connected via CAN bus, the left and right ShiftX3 buttons will automatically trigger corresponding left and right navigation actions on the RaceCapture dashboard. | |||

[file:https://i.imgur.com/CSQfW4s.gif] | |||

==Disco Lights Demo== | ==Disco Lights Demo== | ||

| Line 118: | Line 89: | ||

===Script=== | ===Script=== | ||

Available as a scripting preset - or you can copy and paste this entire script into the scripting window, replacing any existing script. | |||

This script will randomly set LEDs with different colors and the display will update with random numbers. | This script will randomly set LEDs with different colors and the display will update with random numbers. | ||

| Line 141: | Line 112: | ||

This script configures just a sequential shift light, and update gear display. | This script configures just a sequential shift light, and update gear display. | ||

===Script=== | ===Script (Gear is calculated from RPM and Speed)=== | ||

Available as a scripting preset - or you can copy and paste this entire script into the scripting window, replacing any existing script. | |||

* Default is reading RPM from the channel named "RPM" | * Default is reading RPM from the channel named "RPM" | ||

| Line 162: | Line 133: | ||

sxCfgLinearGraph(0,0,0,7000) --left to right graph, smooth style, 0 - 7000 RPM range | sxCfgLinearGraph(0,0,0,7000) --left to right graph, smooth style, 0 - 7000 RPM range | ||

sxSetLinearThresh(0,0, | sxSetLinearThresh(0,0,3000,0,255,0,0) --green at 3000 RPM | ||

sxSetLinearThresh(1,0,5000,255,255,0,0) --yellow at 5000 RPM | sxSetLinearThresh(1,0,5000,255,255,0,0) --yellow at 5000 RPM | ||

sxSetLinearThresh(2,0,6000,255,0,0,10) --red+flash at 6000 RPM | sxSetLinearThresh(2,0,6000,255,0,0,10) --red+flash at 6000 RPM | ||

| Line 176: | Line 147: | ||

</pre> | </pre> | ||

==Shift Light + Twin Alert + Gear Example== | ===Script (Gear is provided by an existing channel)=== | ||

This script shows a more complete example that demos a sequential shift light + two alerts. | Available as a scripting preset - or you can copy and paste this entire script into the scripting window, replacing any existing script. | ||

* Default is reading RPM from the channel named "RPM" | |||

* Default is reading the Gear channel with the channel name "Gear" | |||

<pre> | |||

setTickRate(30) | |||

-- Set ShiftX3 configuration parameters with default parameters | |||

-- orientation: 0=normal, 1=inverted (display above LED bar) | |||

-- brightness: 0-100%, 0 = auto brightness | |||

-- can bus: 0=CAN1, 1=CAN2 | |||

sxSetConfig(0,0,1) | |||

--config shift light | |||

sxCfgLinearGraph(0,0,0,7000) --left to right graph, smooth style, 0 - 7000 RPM range | |||

sxSetLinearThresh(0,0,3000,0,255,0,0) --green at 3000 RPM | |||

sxSetLinearThresh(1,0,5000,255,255,0,0) --yellow at 5000 RPM | |||

sxSetLinearThresh(2,0,6000,255,0,0,10) --red+flash at 6000 RPM | |||

function onTick() | |||

sxUpdateLinearGraph(getChannel("RPM")) | |||

sxSetDisplay(0, getChannel("Gear")) | |||

end | |||

</pre> | |||

==Shift Light + Twin Alert + Gear Example (Gear calculated by RPM and Speed)== | |||

This script shows a more complete example that demos a sequential shift light + two alerts + Gear indicator. | |||

Available as a scripting preset - or you can copy and paste this entire script into the scripting window, replacing any existing script. | |||

Assumptions: | Assumptions: | ||

* Engine Temperature on the 1st alert LED, connected to first analog channel - channel name "EngineTemp" | * Engine Temperature on the 1st alert LED, connected to first analog channel - channel name "EngineTemp" | ||

* Oil Pressure on the 2nd alert LED, connected to second analog channel - channel name "OilPress" | * Oil Pressure on the 2nd alert LED, connected to second analog channel - channel name "OilPress" | ||

* Gear channel | * Gear channel already exists, named "Gear" | ||

Edit the script to change the analog channels you want to monitor. | Edit the script to change the analog channels you want to monitor. | ||

| Line 200: | Line 201: | ||

sxCfgLinearGraph(0,0,0,7000) --left to right graph, smooth style, 0 - 7000 RPM range | sxCfgLinearGraph(0,0,0,7000) --left to right graph, smooth style, 0 - 7000 RPM range | ||

sxSetLinearThresh(0,0, | sxSetLinearThresh(0,0,3000,0,255,0,0) --green at 3000 RPM | ||

sxSetLinearThresh(1,0,5000,255,255,0,0) --yellow at 5000 RPM | sxSetLinearThresh(1,0,5000,255,255,0,0) --yellow at 5000 RPM | ||

sxSetLinearThresh(2,0,6000,255,0,0,10) --red+flash at 6000 RPM | sxSetLinearThresh(2,0,6000,255,0,0,10) --red+flash at 6000 RPM | ||

| Line 224: | Line 225: | ||

setChannel(gearId, gear) | setChannel(gearId, gear) | ||

sxSetDisplay(0, gear) | sxSetDisplay(0, gear) | ||

--update engine temp alert | |||

sxUpdateAlert(0, getChannel("EngineTemp")) | |||

--update oil pressure alert | |||

sxUpdateAlert(1, getChannel("OilPress")) | |||

end</pre> | |||

==Shift Light + Twin Alert + Gear Example (Existing gear channel provided by ECU)== | |||

This script shows a more complete example that demos a sequential shift light + two alerts. | |||

Available as a scripting preset - or you can copy and paste this entire script into the scripting window, replacing any existing script. | |||

Assumptions: | |||

* Engine Temperature on the 1st alert LED, connected to first analog channel - channel name "EngineTemp" | |||

* Oil Pressure on the 2nd alert LED, connected to second analog channel - channel name "OilPress" | |||

* Gear channel already exists (provided by ECU) and is named "Gear" | |||

Edit the script to change the analog channels you want to monitor. | |||

===Script=== | |||

Copy and paste this entire script into the scripting window, replacing any existing script. | |||

<pre> | |||

setTickRate(30) | |||

-- Set ShiftX3 configuration parameters with default parameters | |||

-- orientation: 0=normal, 1=inverted (display above LED bar) | |||

-- brightness: 0-100%, 0 = auto brightness | |||

-- can bus: 0=CAN1, 1=CAN2 | |||

sxSetConfig(0,0,1) | |||

--config shift light | |||

sxCfgLinearGraph(0,0,0,7000) --left to right graph, smooth style, 0 - 7000 RPM range | |||

sxSetLinearThresh(0,0,3000,0,255,0,0) --green at 3000 RPM | |||

sxSetLinearThresh(1,0,5000,255,255,0,0) --yellow at 5000 RPM | |||

sxSetLinearThresh(2,0,6000,255,0,0,10) --red+flash at 6000 RPM | |||

--configure first alert (right LED) as engine temperature (F) | |||

sxSetAlertThresh(0,0,205,255,255,0,0) --yellow warning at 205F | |||

sxSetAlertThresh(0,1,225,255,0,0,10) -- red flash at 225F | |||

--configure second alert (left LED) as oil pressure (PSI) | |||

sxSetAlertThresh(1,0,0,0,0,255,10) --red flash below 15 psi | |||

sxSetAlertThresh(1,1,15,255,255,0,5) --yellow flash 15-20 PSI | |||

sxSetAlertThresh(1,2,20,0,0,0,0) --above 20, no alert | |||

function onTick() | |||

sxUpdateLinearGraph(getChannel("RPM")) | |||

sxSetDisplay(0, getChannel("Gear")) | |||

--update engine temp alert | --update engine temp alert | ||

| Line 353: | Line 404: | ||

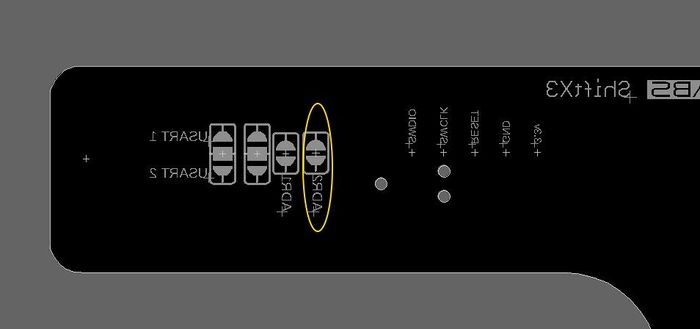

==Hardware / CAN configuration== | ==Hardware / CAN configuration== | ||

===CAN Termination=== | ===CAN Termination=== | ||

CAN termination is | CAN termination is disabled by default. To enable termination, bridge the '''CAN Term''' jumper on the bottom of the ShiftX3 circuit board. | ||

===CAN Base Address=== | ===CAN Base Address=== | ||

| Line 372: | Line 423: | ||

===CAN Baud Rate=== | ===CAN Baud Rate=== | ||

The default CAN baud rate is | The default CAN baud rate is 1MB. You can switch to 500K by breaking the ADR2 Jumper on the bottom of the ShiftX3 board. | ||

{| class="wikitable" style="text-align:center; width:700px; height:200px;" | {| class="wikitable" style="text-align:center; width:700px; height:200px;" | ||

| Line 381: | Line 432: | ||

|- | |- | ||

| Closed (Default setting) | | Closed (Default setting) | ||

| | | 1MB | ||

|- | |- | ||

| Open | | Open | ||

| | | 500K | ||

|} | |} | ||

[[Image:ShiftXCanBaudRateJumper.jpg|700px]] | |||

==ShiftX3 CAN Protocol== | ==ShiftX3 CAN Protocol== | ||

Latest revision as of 04:56, 5 September 2023

Introduction

Parts in the Kit

- ShiftX3

Compatibility

ShiftX3 is compatible with:

- RaceCapture/Track MK2,MK3

- RaceCapture/Pro MK2,MK3,MK4

- RaceCapture/Apex

- PodiumConnect MK1,MK2

Note: Not compatible with RaceCapture/Track MK1.

Firmware Requirements

ShiftX3 requires RaceCapture/PodiumConnect firmware 2.15.0 or higher. Download the latest firmware

Connection and Installation

Mounting ShiftX3

Attach ShiftX3 with #6 mounting screws and tighten until snug.

- Note: You can install with the 7 segment display above or below the LED strip; see the setup instructions for selecting the orientation.

Dimensions

- ShiftX3 with enclosure 136 x 32 x 9.46 mm (5.35 x 1.26 x .37 inches)

- Enclosure DXF and PDF drawing File:ShiftX3 enclosure.zip

Plug and Play connection

- Note: ShiftX3 requires 12v power, via RaceCapture's own power connection.

ShiftX3 connects effortlessly into our plug and play connector system, using the recommended cabling accessories:

- Dual CAN splitter

- CAN extension (choose your desired length)

- Inline CAN terminator

Connect the Dual CAN splitter into the CAN1/CAN2 port of your main system:

Then connect your CAN extension cable to the "B" port of the Dual CAN splitter:

At the opposite end of the CAN extension, attach the inline CAN terminator:

Finally, attach ShiftX3 to the other end of the Terminator to complete the installation.

Direct wire connection

You can connect ShiftX3 into a non plug and play system by using the following cabling accessories:

Connect the pigtail wires to your system:

- Green to CAN2 High

- White to CAN2 Low

- Red to +12v (same power connection for your system)

- Black to Ground (same ground connection for your system)

Then connect the pigtail to the inline CAN terminator.

Finally, attach ShiftX3 to the other end of the Terminator to complete the installation.

Using ShiftX3

The LEDs and display on ShiftX3 are controlled by RaceCapture's Lua scripting capabilities. Built-in functions provide access to ShiftX3's capabilities. See the ShiftX3 Lua scripting reference for additional details.

Note: Ready to go scripts may be available as a preset. When in the Scripting view, press the Presets button to access a list of pre-configured scripts. Be sure to press the cloud update button to get the latest set of presets.

Once ShiftX3 is powered and connected via CAN bus, the left and right ShiftX3 buttons will automatically trigger corresponding left and right navigation actions on the RaceCapture dashboard.

[file: ]

]

Disco Lights Demo

This is a test script that exercises all of the LEDs and the 7 segment display on ShiftX3. You can use this as a first time test, as it does not rely on any sensors.

Script

Available as a scripting preset - or you can copy and paste this entire script into the scripting window, replacing any existing script.

This script will randomly set LEDs with different colors and the display will update with random numbers.

setTickRate(10)

function rndc()

return math.random(0,255)

end

function onTick()

for i=0,9,1 do

sxSetLed(i,1,rndc(),rndc(),rndc(),0)

end

-- ascii characters between 0 and 9

sxSetDisplay(0, math.random(0,9))

end

Sequential shift light + Gear indicator

This script configures just a sequential shift light, and update gear display.

Script (Gear is calculated from RPM and Speed)

Available as a scripting preset - or you can copy and paste this entire script into the scripting window, replacing any existing script.

- Default is reading RPM from the channel named "RPM"

- Default is creating the Gear channel with the channel name "Gear"

setTickRate(30)

-- Set ShiftX3 configuration parameters with default parameters

-- orientation: 0=normal, 1=inverted (display above LED bar)

-- brightness: 0-100%, 0 = auto brightness

-- can bus: 0=CAN1, 1=CAN2

sxSetConfig(0,0,1)

--create gear channel

gearId = addChannel("Gear", 10, 0, 0, 6)

--config shift light

sxCfgLinearGraph(0,0,0,7000) --left to right graph, smooth style, 0 - 7000 RPM range

sxSetLinearThresh(0,0,3000,0,255,0,0) --green at 3000 RPM

sxSetLinearThresh(1,0,5000,255,255,0,0) --yellow at 5000 RPM

sxSetLinearThresh(2,0,6000,255,0,0,10) --red+flash at 6000 RPM

function onTick()

sxUpdateLinearGraph(getChannel("RPM"))

-- calculate gear: tire diameter(cm), final gear ratio, individual gear ratios 1-6

local gear = calcGear(62.7, 3.45, 4.23, 2.52, 1.66, 1.22, 1.0, 0.8)

setChannel(gearId, gear)

sxSetDisplay(0, gear)

end

Script (Gear is provided by an existing channel)

Available as a scripting preset - or you can copy and paste this entire script into the scripting window, replacing any existing script.

- Default is reading RPM from the channel named "RPM"

- Default is reading the Gear channel with the channel name "Gear"

setTickRate(30)

-- Set ShiftX3 configuration parameters with default parameters

-- orientation: 0=normal, 1=inverted (display above LED bar)

-- brightness: 0-100%, 0 = auto brightness

-- can bus: 0=CAN1, 1=CAN2

sxSetConfig(0,0,1)

--config shift light

sxCfgLinearGraph(0,0,0,7000) --left to right graph, smooth style, 0 - 7000 RPM range

sxSetLinearThresh(0,0,3000,0,255,0,0) --green at 3000 RPM

sxSetLinearThresh(1,0,5000,255,255,0,0) --yellow at 5000 RPM

sxSetLinearThresh(2,0,6000,255,0,0,10) --red+flash at 6000 RPM

function onTick()

sxUpdateLinearGraph(getChannel("RPM"))

sxSetDisplay(0, getChannel("Gear"))

end

Shift Light + Twin Alert + Gear Example (Gear calculated by RPM and Speed)

This script shows a more complete example that demos a sequential shift light + two alerts + Gear indicator.

Available as a scripting preset - or you can copy and paste this entire script into the scripting window, replacing any existing script.

Assumptions:

- Engine Temperature on the 1st alert LED, connected to first analog channel - channel name "EngineTemp"

- Oil Pressure on the 2nd alert LED, connected to second analog channel - channel name "OilPress"

- Gear channel already exists, named "Gear"

Edit the script to change the analog channels you want to monitor.

Script

Copy and paste this entire script into the scripting window, replacing any existing script.

setTickRate(30)

-- Set ShiftX3 configuration parameters with default parameters

-- orientation: 0=normal, 1=inverted (display above LED bar)

-- brightness: 0-100%, 0 = auto brightness

-- can bus: 0=CAN1, 1=CAN2

sxSetConfig(0,0,1)

--config shift light

sxCfgLinearGraph(0,0,0,7000) --left to right graph, smooth style, 0 - 7000 RPM range

sxSetLinearThresh(0,0,3000,0,255,0,0) --green at 3000 RPM

sxSetLinearThresh(1,0,5000,255,255,0,0) --yellow at 5000 RPM

sxSetLinearThresh(2,0,6000,255,0,0,10) --red+flash at 6000 RPM

--configure first alert (right LED) as engine temperature (F)

sxSetAlertThresh(0,0,205,255,255,0,0) --yellow warning at 205F

sxSetAlertThresh(0,1,225,255,0,0,10) -- red flash at 225F

--configure second alert (left LED) as oil pressure (PSI)

sxSetAlertThresh(1,0,0,0,0,255,10) --red flash below 15 psi

sxSetAlertThresh(1,1,15,255,255,0,5) --yellow flash 15-20 PSI

sxSetAlertThresh(1,2,20,0,0,0,0) --above 20, no alert

--create gear channel

gearId = addChannel("Gear", 10, 0, 0, 6)

function onTick()

--update RPM

sxUpdateLinearGraph(getChannel("RPM"))

-- calculate gear: tire diameter(cm), final gear ratio, individual gear ratios 1-6

local gear = calcGear(62.7, 3.45, 4.23, 2.52, 1.66, 1.22, 1.0, 0.8)

setChannel(gearId, gear)

sxSetDisplay(0, gear)

--update engine temp alert

sxUpdateAlert(0, getChannel("EngineTemp"))

--update oil pressure alert

sxUpdateAlert(1, getChannel("OilPress"))

end

Shift Light + Twin Alert + Gear Example (Existing gear channel provided by ECU)

This script shows a more complete example that demos a sequential shift light + two alerts.

Available as a scripting preset - or you can copy and paste this entire script into the scripting window, replacing any existing script.

Assumptions:

- Engine Temperature on the 1st alert LED, connected to first analog channel - channel name "EngineTemp"

- Oil Pressure on the 2nd alert LED, connected to second analog channel - channel name "OilPress"

- Gear channel already exists (provided by ECU) and is named "Gear"

Edit the script to change the analog channels you want to monitor.

Script

Copy and paste this entire script into the scripting window, replacing any existing script.

setTickRate(30)

-- Set ShiftX3 configuration parameters with default parameters

-- orientation: 0=normal, 1=inverted (display above LED bar)

-- brightness: 0-100%, 0 = auto brightness

-- can bus: 0=CAN1, 1=CAN2

sxSetConfig(0,0,1)

--config shift light

sxCfgLinearGraph(0,0,0,7000) --left to right graph, smooth style, 0 - 7000 RPM range

sxSetLinearThresh(0,0,3000,0,255,0,0) --green at 3000 RPM

sxSetLinearThresh(1,0,5000,255,255,0,0) --yellow at 5000 RPM

sxSetLinearThresh(2,0,6000,255,0,0,10) --red+flash at 6000 RPM

--configure first alert (right LED) as engine temperature (F)

sxSetAlertThresh(0,0,205,255,255,0,0) --yellow warning at 205F

sxSetAlertThresh(0,1,225,255,0,0,10) -- red flash at 225F

--configure second alert (left LED) as oil pressure (PSI)

sxSetAlertThresh(1,0,0,0,0,255,10) --red flash below 15 psi

sxSetAlertThresh(1,1,15,255,255,0,5) --yellow flash 15-20 PSI

sxSetAlertThresh(1,2,20,0,0,0,0) --above 20, no alert

function onTick()

sxUpdateLinearGraph(getChannel("RPM"))

sxSetDisplay(0, getChannel("Gear"))

--update engine temp alert

sxUpdateAlert(0, getChannel("EngineTemp"))

--update oil pressure alert

sxUpdateAlert(1, getChannel("OilPress"))

end

Predictive Lap Timer Indicator

This script enables predictive lap time visualization.

How it works

A bar extends left or right from the center of the linear graph:

- Green bar extending to the right indicates you're beating the best time

- Red bar extending to the left means you're falling behind.

- When you're close to the best time, the center blue LED illuminates.

Notes:

- The script is designed for a +/- 10 second maximum delta - so if you're ahead or behind by 10 seconds, the linear graph will be fully illuminated center-right, or center-left.

- You will need to complete a a full lap to train the predictive timer before the graph will update.

Script

Copy and paste this entire script into the scripting window, replacing any existing script.

-- Predictive time visualizer --save best lap time bestTime = 0 -- Set ShiftX3 configuration parameters with default parameters -- orientation: 0=normal, 1=inverted (display above LED bar) -- brightness: 0-100%, 0 = auto brightness -- can bus: 0=CAN1, 1=CAN2 sxSetConfig(0,0,1) --config shift light sxCfgLinearGraph(1,0,0,200) --center-out graph, linear style, +/- 10.0 seconds in 0.1 sec resolution sxSetLinearThresh(0,0,0,255,0,0,0) --red if you're falling behind best lap sxSetLinearThresh(1,0,80,0,0,255,0) --blue if you're close to best lap sxSetLinearThresh(2,0,110,0,255,0,0) --green if you're beating best lap setTickRate(30) function onTick() local predTime = getPredTime() local timeDiff = (bestTime - predTime) * 60 -- rail values timeDiff = math.max(timeDiff, -10) timeDiff = math.min(timeDiff, 10) --scale values from +/- 10 sec to a 0-200 scale timeDiff = (timeDiff + 10) * 10 sxUpdateLinearGraph(timeDiff) --update best lap time if an updated lap time is available local lastLapTime = getLapTime() if lastLapTime < bestTime or bestTime == 0 then bestTime = lastLapTime end end

Boost Gauge

This script visualizes a single analog input channel on the linear graph.

How it works

The script configures the linear graph, then reads an analog channel and updates the graph with the current value. In this case, the value represents boost level measured from a MAP sensor.

Assumptions

- MAP sensor is on the channel named "MAP"

Script

Copy and paste this entire script into the scripting window, replacing any existing script.

setTickRate(30)

-- Set ShiftX3 configuration parameters with default parameters

-- orientation: 0=normal, 1=inverted (display above LED bar)

-- brightness: 0-100%, 0 = auto brightness

-- can bus: 0=CAN1, 1=CAN2

sxSetConfig(0,0,1)

--config shift light

sxCfgLinearGraph(0,0,0, 20) --left to right graph, linear style, 0 - 20 PSI boost

sxSetLinearThresh(0,0,0,0,255,0,0) --green starting at no boost

sxSetLinearThresh(1,0,10,255,255,0,0) --yellow starting at 10 PSI boost

sxSetLinearThresh(2,0,15,255,0,0,10) --red+flash at 15 PSI boost

function onTick()

local map = getChannel("MAP")

if map ~= nil then

--convert to PSI boost

local boost = math.max(map - 100, 0) * .145038

sxUpdateLinearGraph(boost)

end

end

ShiftX3 CAN bus API

Overview

The CAN bus API provides the configuration and control interface for ShiftX3.

Two styles of control are available:

- Low level control of LEDs - the ability to discretely set LED color and flash behavior

- High level control - configuring alert thresholds and linear graph up front, and then providing simple value updates

Hardware / CAN configuration

CAN Termination

CAN termination is disabled by default. To enable termination, bridge the CAN Term jumper on the bottom of the ShiftX3 circuit board.

CAN Base Address

The default CAN base address is 931328 (0xE3600). You can change it by breaking the trace bridging the ADR1 jumper on the bottom of the ShiftX3 circuit board.

| ADR1 jumper setting | Base address |

|---|---|

| Closed (Default setting) | 931328 (0xE3600) |

| Open | 931584 (0xE3700) |

CAN Baud Rate

The default CAN baud rate is 1MB. You can switch to 500K by breaking the ADR2 Jumper on the bottom of the ShiftX3 board.

| ADR2 jumper setting | Baud Rate |

|---|---|

| Closed (Default setting) | 1MB |

| Open | 500K |

ShiftX3 CAN Protocol

Configuration / Runtime Options

Set Configuration Parameters Group 1

Sets various configuration options.

CAN ID: Base + 3

| Offset | What | Value |

|---|---|---|

| 0 | Brightness | 0 - 100; 1 = dimmest; 100 = brightest; 0 = automatic brightness control using built-in light sensor. |

| 1 | Automatic brightness scaling (Optional) | 0-255; default=61. adjust this value to adjust the relative gain of the built-in light sensor when in automatic brightness mode. |

| 2 | Display orientation | 0: 7-segment display is below shift light; 1: 7-segment display is above shift light |

Set Display

Directly sets the value of the 7 segment display.

CAN ID: Base + 50

| Offset | What | Value |

|---|---|---|

| 0 | Digit index | 0 (must be 0) |

| 1 | Character | ASCII value of character to display |

The value of the display is set by the ASCII coded value. To set a numeric value, offset the value by 48: e.g. 48 = 0, 49 = 1, etc.

Most alphanumeric characters are supported as well, also via ASCII representation.

Set Discrete LED

A low level function to directly set any LED on the device.

CAN ID: Base + 10

| Offset | What | Value |

|---|---|---|

| 0 | LED index | 0 -> # of LEDs on device |

| 1 | Number of LEDs to set | 0 -> # of LEDs on device (0 = set all remaining) |

| 2 | Red | 0 - 255 |

| 3 | Green | 0 - 255 |

| 4 | Blue | 0 - 255 |

| 5 | Flash | 0-10Hz (0 = full on) |

Alert Indicators

Alert Indicators are typically single LEDs or a group of LEDs treated as one logical unit. This is defined by the hardware configuration of the device.

Set Alert

Directly set an alert indicator

CAN ID: Base + 20

| Offset | What | Value |

|---|---|---|

| 0 | Alert ID | 0 -> # of Alert indicators |

| 1 | Red | 0 - 255 |

| 2 | Green | 0 - 255 |

| 3 | Blue | 0 - 255 |

| 4 | Flash | 0-10Hz (0 = full on) |

Set Alert Threshold

Configures an alert threshold. Up to 5 thresholds can be configured per alert indicator.

Notes:

- If the current value is greater than the last threshold, then the last threshold is selected.

- The first threshold may have a threshold value >= 0; remaining thresholds must be > 0

CAN ID: Base + 21

| Offset | What | Value |

|---|---|---|

| 0 | Alert ID | 0 -> # of Alert indicators |

| 1 | Threshold ID | 0 - 4 |

| 2 | Threshold (low byte) | |

| 3 | Threshold (high byte) | |

| 4 | Red | 0 - 255 |

| 5 | Green | 0 - 255 |

| 6 | Blue | 0 - 255 |

| 7 | Flash Hz | 0 - 10 (0 = full on) |

Update Current Alert Value

Updates the current value for an alert indicator. The configured alert thresholds will be applied to the current value.

CAN ID: Base + 22

| Offset | What | Value |

|---|---|---|

| 0 | Alert ID | 0 -> # of Alert indicators |

| 1 | Value (low byte) | |

| 2 | Value (high byte) |

Linear Graph

The linear graph mode provides visualizations for common scenarios:

- Sequential RPM shift light where the progression is stepped

- Linear bar graph to linearly indicate a sensor value

- Center left/right graph to indicate +/- performance against a reference - such as visualizing current predictive time vs best time

Power up default configuration

Upon power up the linear graph is configured:

- Rendering style: left->right

- Linear style: stepped

- Low Range: 0

- High Range: N/A

- Threshold :

- Threshold value: 3000 / segment length: 3 / color RGB: (0, 255, 0) / flash: 0

- Threshold value: 5000 / segment length: 5 / color RGB: (0, 255, 255) / flash: 0

- Threshold value: 7000 / segment length: 7 / color RGB: (255, 0, 0) / flash: 5

Configure Linear Graph

Configures the options for the linear graph portion of the device.

Rendering style:

- If left->right, linear graph illuminates left to right

- If centered, values below the mid-point in the range extend from the center to the left, and values above the mid-point extend from the center to the right.

- If right->left, linear graph illuminates right to left

Linear style:

- if smooth, graph length is updated smoothly by interpolating the current value in-between LEDs

- If stepped, creates the visual effect of stepped progressions by setting the segment length of the threshold configuration. High Range of configuration is ignored.

CAN ID: Base + 40

| Offset | What | Value |

|---|---|---|

| 0 | Rendering Style | 0 = left->right, 1=center, 2=right->left |

| 1 | Linear Style | 0 = Smooth / interpolated, 1 = stepped |

| 2 | Low Range (low byte) | |

| 3 | Low Range (high byte) | |

| 4 | High Range (low byte) | (ignored if linear style = stepped) |

| 5 | High Range (high byte) | (ignored if linear style = stepped) |

Set Linear Graph Threshold

Configures a linear threshold. Up to 5 thresholds can be configured

Notes:

- If the current value is greater than the last threshold, then the last threshold is selected.

- The first threshold may have a threshold value >= 0; remaining thresholds must be > 0

CAN ID: Base + 41

| Offset | What | Value |

|---|---|---|

| 0 | Threshold ID | 0 - 4 |

| 1 | Segment Length | 0 -> # of LEDs on device (ignored if linear style is ‘smooth’) |

| 2 | Threshold (low byte) | |

| 3 | Threshold (high byte) | |

| 4 | Red | 0 - 255 |

| 5 | Green | 0 - 255 |

| 6 | Blue | 0 - 255 |

| 7 | Flash Hz | 0 - 10 (0 = full on) |

Update Current Linear Graph Value

Updates the current value for the linear graph

CAN ID: Base + 42

| Offset | What | Value |

|---|---|---|

| 0 | Value (low byte) | |

| 1 | Value (high byte) |

Notifications

Notifications related to events broadcasted from ShiftX3

Announcement

Broadcast by the device upon power up

CAN ID: Base + 0

| Offset | What | Value |

|---|---|---|

| 0 | Total LEDs | Total number of LEDs on the device |

| 1 | Alert Indicators | Number of logical alert indicators |

| 2 | Linear Bar Graph Length | Number of LEDs in linear graph |

| 3 | Major Version | Firmware major version number |

| 4 | Minor Version | Firmware minor version number |

| 5 | Patch Version | Firmware patch version number |

Statistics

Statistics information, broadcast periodically by device

CAN ID: Base + 2

| Offset | What | Value |

|---|---|---|

| 0 | Major Version | Firmware major version number |

| 1 | Minor Version | Firmware minor version number |

| 2 | Patch Version | Firmware patch version number |

Button State

Indicates a change in the button state

CAN ID: Base + 60

| Offset | What | Value |

|---|---|---|

| 0 | Button state | 1 = button is pressed; 0 = button |

| 1 | Button ID | ID of button |