RaceCapturePro Lua Scripting Examples: Difference between revisions

| (84 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

==How to set a script in the RaceCapture app== | |||

[https://youtu.be/SuHDvt3W9jc HowTo video: set custom script] | |||

==API Reference== | ==API Reference== | ||

'''[[RaceCapturePro_Lua_Scripting|Complete API Reference]]''' | '''[[RaceCapturePro_Lua_Scripting|Complete API Reference]]''' | ||

=OBDII tricks= | |||

[https://en.wikipedia.org/wiki/OBD-II_PIDs Complete OBDII PID reference] | |||

==Clear current trouble codes== | |||

This script clears any current trouble codes every 10 seconds. Clearing the code requires transmitting an OBDII command to ID 0x7DF with mode 4 specified. No other parameters are specified. | |||

<pre> | |||

setTickRate(1) | |||

count = 0 | |||

function onTick() | |||

checkClearCodes() | |||

end | |||

function checkClearCodes() | |||

if count % 10 == 0 then | |||

print('clearing codes') | |||

txCAN(0, 0x7df, 0, {1,4}) | |||

end | |||

end | |||

</pre> | |||

==Query and Decode Diagnostic Trouble Code== | |||

This script queries for a DTC, and if found, prints the decoded trouble code and the raw data. | |||

<pre> | |||

--This example queries for and reads the first available DTC, if present. | |||

setTickRate(1) | |||

--P=Powertrain, C=Chassis, B=Body, U=Network | |||

prefixes = {'P','C','B','U'} | |||

digits = {'0','1','2','3','4','5','6','7','8','9','A','B','C','D','E','F'} | |||

function toDigit(v) | |||

return digits[v+1] | |||

end | |||

function printDTC(data) | |||

local dtc | |||

local a = data[3] | |||

local b = data[4] | |||

local prefix = prefixes[bit.band(bit.rshift(a, 6), 0x03) + 1] | |||

local c2 = bit.band(bit.rshift(a, 4), 0x03) | |||

local c3 = bit.band(a, 0x0f) | |||

local c4 = bit.band(bit.rshift(b, 4), 0x0F) | |||

local c5 = bit.band(b, 0x0F) | |||

local code = prefix ..toDigit(c2) ..toDigit(c3) ..toDigit(c4) ..toDigit(c5) | |||

println('Found DTC: ' ..code) | |||

end | |||

function printRawDTC(data) | |||

print('Raw DTC bytes: ') | |||

--print the remaining 6 bytes, | |||

--this raw data holds the trouble codes | |||

for i=1, #data do print(' ' ..data[i]) end | |||

println('') | |||

end | |||

function checkDTCResponse() | |||

local attempts = 0 | |||

while attempts < 50 do | |||

local id,ext, data = rxCAN(0, 10) | |||

if id ~= nil and ext == 0 and id == 0x7e8 then | |||

if data[2] == 0x43 then | |||

if data[1] > 2 then | |||

printRawDTC(data) | |||

printDTC(data) | |||

else | |||

println('No DTC Found') | |||

end | |||

return | |||

end | |||

end | |||

attempts = attempts + 1 | |||

end | |||

end | |||

function sendCheckDTC() | |||

println('Sending check DTC') | |||

txCAN(0, 0x7df, 0, {1,3}) | |||

end | |||

function onTick() | |||

sendCheckDTC() | |||

checkDTCResponse() | |||

end | |||

</pre> | |||

==Display OBDII Codes as a channel and allow driver to reset the OBDII Codes with a button== | |||

This script creates a virtual channel called ''OBDIICodes'' and sets it to the first OBDII Trouble Code found (It will not have the alpha prefix (Ie P, C , B, or U), but will just have up to 4 digits. You can then use these digits to figure out the P code. Ie, if 155 is returned, your OBDII code would be P0155. If -1 is shown for the ''OBDIICodes'' channel that means RaceCapture has not received any codes from the ECU yet. If 0 is shown for ''OBDIICodes'' channel that means the ECU sent back P0000 which means there are no OBDII trouble codes in the ECU. This channel will be logged and sent via telemetry just like a regular channel. If more than one OBDII code is found, it will cycle setting the ''OBDIICodes'' channel to the first 2-3 OBDII codes that were returned. It will cycle to the next code every couple of seconds. | |||

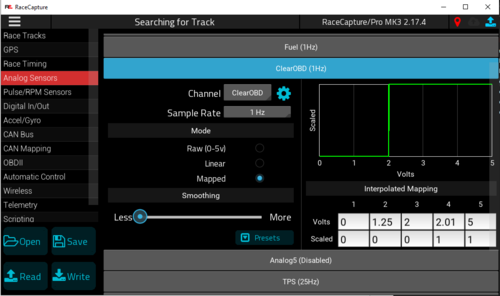

I also added the ability for the driver to reset the OBDII Trouble codes using an external button. This button needs to be mapped to an Analog or GPIO channel called ''ClearOBD''. It will reset the vehicle's OBDII codes and reset the ''OBDIICodes'' channel to -1. | |||

[[Image:ClearOBDChannel.png|500px]] | |||

Here is a [https://www.youtube.com/watch?v=uLqjKFXaF8c video of the functionality in action.] | |||

<pre> | |||

--Modified by Scott Barton of ProFormance Coaching for Autosport Labs Community | |||

tickRate = 5 | |||

setTickRate(tickRate) | |||

counter=0 | |||

--P=Powertrain, C=Chassis, B=Body, U=Network | |||

prefixes = {'P','C','B','U'} | |||

digits = {'0','1','2','3','4','5','6','7','8','9','A','B','C','D','E','F'} | |||

OBDCodes = {'-1'} | |||

currCode = 1 | |||

addChannel("OBDIICodes", 1, 0) | |||

setChannel("OBDIICodes", -1)-- Some car manufactures send P0000 if there are no fault codes; therefore we will use -1 to know that no codes have been returned yet | |||

function clearOBDCodes() | |||

for i=#OBDCodes, 1, -1 do | |||

OBDCodes[i] = nil | |||

end | |||

OBDCodes[1] = '-1' | |||

end | |||

function addOBDCode(code) | |||

local codeFound = false | |||

for i=1, #OBDCodes do | |||

if OBDCodes[i] == '-1' or OBDCodes[i] == 0 then OBDCodes[i] = nil end | |||

if OBDCodes[i] == code then codeFound=true end | |||

end | |||

if not codeFound then | |||

OBDCodes[#OBDCodes+1] = code | |||

println(#OBDCodes ..' Total OBDII Codes Found So Far') | |||

end | |||

end | |||

function displayOBDCodes() | |||

counter = counter+1 | |||

if counter == 3*tickRate then --seconds since last update | |||

currCode = currCode+1 | |||

if currCode>#OBDCodes then currCode=1 end | |||

--println('Updating OBDII Code ' ..currCode ..' ' ..OBDCodes[currCode]) | |||

counter = 0 | |||

end | |||

setChannel("OBDIICodes", OBDCodes[currCode]) | |||

end | |||

function checkClearCodes(canChan) | |||

local ClrOBD = getChannel("ClearOBD ") --Must create an analog or GPIO channel called ClearOBD in your settings and map it to read 1 or higher when you push the external button wired to that input | |||

if ClrOBD ~= nil and ClrOBD > 0 then | |||

println('Clearing OBDII codes') | |||

txCAN(canChan, 0x7df, 0, {1,4}) --sends reset OBDII codes command to ECU | |||

clearOBDCodes() | |||

setChannel("OBDIICodes", -1) | |||

end | |||

end | |||

function toDigit(v) | |||

return digits[v+1] | |||

end | |||

function printDTC(data) | |||

local dtc | |||

local a = data[3] | |||

local b = data[4] | |||

local prefix = prefixes[bit.band(bit.rshift(a, 6), 0x03) + 1] | |||

local c2 = bit.band(bit.rshift(a, 4), 0x03) | |||

local c3 = bit.band(a, 0x0f) | |||

local c4 = bit.band(bit.rshift(b, 4), 0x0F) | |||

local c5 = bit.band(b, 0x0F) | |||

local code = toDigit(c2) ..toDigit(c3) ..toDigit(c4) ..toDigit(c5) | |||

addOBDCode(code) | |||

--setChannel("OBDIICodes", code) | |||

code = prefix ..code | |||

println('Found DTC: ' ..code) | |||

a = data[5] | |||

b = data[6] | |||

local d2 = bit.band(bit.rshift(a, 4), 0x03) | |||

local d3 = bit.band(a, 0x0f) | |||

local d4 = bit.band(bit.rshift(b, 4), 0x0F) | |||

local d5 = bit.band(b, 0x0F) | |||

local code2 = toDigit(d2) ..toDigit(d3) ..toDigit(d4) ..toDigit(d5) | |||

if tonumber(code2) ~= nil and tonumber(code2)>1 then | |||

addOBDCode(code2) | |||

code2 = prefix ..code2 | |||

println('Found 2nd DTC: ' ..code2) | |||

end | |||

a = data[7] | |||

b = data[8] | |||

local e2 = bit.band(bit.rshift(a, 4), 0x03) | |||

local e3 = bit.band(a, 0x0f) | |||

local e4 = bit.band(bit.rshift(b, 4), 0x0F) | |||

local e5 = bit.band(b, 0x0F) | |||

local code3 = toDigit(e2) ..toDigit(e3) ..toDigit(e4) ..toDigit(e5) | |||

if tonumber(code3) ~= nil and tonumber(code3)>1 then | |||

addOBDCode(code3) | |||

code3 = prefix ..code3 | |||

println('Found 3rd DTC: ' ..code3) | |||

end | |||

end | |||

function printRawDTC(data) | |||

print('Raw DTC bytes: ') | |||

--print the remaining 6 bytes, | |||

--this raw data holds the trouble codes | |||

for i=1, #data do print(' ' ..data[i]) end | |||

println('') | |||

end | |||

function checkDTCResponse(canChan) | |||

local attempts = 0 | |||

while attempts < 50 do | |||

local id,ext, data = rxCAN(canChan, 10) | |||

if id ~= nil and ext == 0 and id == 0x7e8 then | |||

if data[2] == 0x43 then | |||

if data[1] > 2 then | |||

printRawDTC(data) | |||

printDTC(data) | |||

else | |||

--println('No DTC Found') | |||

end | |||

return | |||

end | |||

end | |||

attempts = attempts + 1 | |||

end | |||

end | |||

function sendCheckDTC(canChan) | |||

--println('Sending check DTC') | |||

txCAN(canChan, 0x7df, 0, {1,3}) | |||

end | |||

function onTick() | |||

sendCheckDTC(1) --0=OBDII is on CAN Channel 1; 1=OBD is on CAN Channel 2 | |||

checkDTCResponse(1) | |||

displayOBDCodes() | |||

checkClearCodes(1) | |||

end | |||

</pre> | |||

=Data filtering= | |||

==Simple RPM Filter== | |||

Got a noisy RPM signal where big spikes show up? This will reject RPM values above a sane threshold. | |||

'''Important''' - make sure the RPM channel in the main RaceCapture/Pro config is '''disabled''', since this virtual channel replaces it. | |||

<pre> | |||

--sample RPM at 10Hz | |||

setTickRate(10) | |||

--set this value to be your sane upper limit | |||

rpmLimit = 10000 | |||

--In the RCP config, ensure the timer channels are disabled | |||

--we will create the virtual channel here | |||

rpmId = addChannel( "RPM", 10, 0, 0, rpmLimit) | |||

rpm = 0 | |||

function doRPM() | |||

local r = getTimerRpm(0) | |||

if r < rpmLimit then | |||

rpm = r | |||

end | |||

setChannel(rpmId, rpm) | |||

end | |||

function onTick() | |||

doRPM() | |||

end | |||

</pre> | |||

=Automatic logging control= | |||

==Automatically Start Logging When Powered On== | ==Automatically Start Logging When Powered On== | ||

This script will automatically start logging the moment RaceCapture/Pro turns on | This script will automatically start logging the moment RaceCapture/Pro turns on | ||

* Note, this will create a file with an incorrect timestamp if GPS lock is not established. | |||

** To get a properly time-stamped file, use the GPS speed triggered approach. | |||

function onTick() | function onTick() | ||

| Line 12: | Line 300: | ||

This script will automatically start logging to SD card when speed exceeds 10MPH and stop when it falls below. | This script will automatically start logging to SD card when speed exceeds 10MPH and stop when it falls below. | ||

<pre> | |||

function onTick() | |||

if getGpsSpeed() > 10 then | |||

startLogging() | |||

else | |||

stopLogging() | |||

end | end | ||

end | |||

</pre> | |||

==Automatically Start Logging when engine is running== | |||

This script will automatically start logging to SD card when battery voltage shows that the engine is running | |||

* When battery voltage is greater than 13 volts, we assume engine is running. | |||

* System battery voltage is tied to the last Analog channel (8) (Note, change this to 7 if RaceCapture/Pro MK2) | |||

<pre> | |||

function onTick() | |||

if getAnalog(8) > 13 then | |||

startLogging() | |||

else | |||

stopLogging() | |||

end | |||

end | |||

</pre> | |||

==Automatically start Logging upon Launch (AutoX / Rally / Hill Climb)== | ==Automatically start Logging upon Launch (AutoX / Rally / Hill Climb)== | ||

| Line 28: | Line 333: | ||

* flipping the ARM switch to 'Off' will stop logging | * flipping the ARM switch to 'Off' will stop logging | ||

<pre> | |||

setTickRate(30) | setTickRate(30) | ||

overRevId = addChannel("OverRev", 10) | |||

function onTick() | function onTick() | ||

local arm = getGpio(0) | local arm = getGpio(0) | ||

| Line 39: | Line 347: | ||

startLogging() | startLogging() | ||

end | end | ||

end | |||

</pre> | |||

=Virtual Channels (AKA Math Channels)= | |||

==Averaging a fuel level reading or other sensor== | |||

This script calculates a moving average to account for fuel slosh. | |||

Assumptions: | |||

* Fuel level is connected to the first analog channel and is calibrated; modify the script to base the reading on other channels as appropriate. | |||

<pre> | |||

--The real analog channel should be named | |||

--something other than FuelLevel | |||

fuel2Id = addChannel("FuelLevel", 10, 0, 0,100,"%") | |||

--change this to make a bigger averaging window | |||

maxAvg = 600 | |||

--600 = 20 seconds averaging at 30Hz tick rate | |||

--do not change | |||

fuelAvg={} | |||

fuel2Index = 1 | |||

function updateFuelAvg(value) | |||

local i | |||

if #fuelAvg == 0 then | |||

--initialize averaging table | |||

for i = 1, maxAvg do fuelAvg[i]=0 end | |||

end | |||

fuelAvg[fuel2Index] = value | |||

fuel2Index = fuel2Index + 1 | |||

if fuel2Index > maxAvg then fuel2Index = 1 end | |||

local sum = 0 | |||

for i = 1, #fuelAvg do | |||

sum = sum + fuelAvg[i] | |||

end | |||

setChannel(fuel2Id, sum / maxAvg) | |||

end | |||

setTickRate(30) | |||

function onTick() | |||

updateFuelAvg(getAnalog(0)) | |||

end | |||

</pre> | |||

==Average two sensor values and set to a virtual channel== | |||

<pre> | |||

--10Hz update | |||

setTickRate(10) | |||

--Create channel: "SensorAvg" | |||

--Sample rate: 10Hz | |||

--Logging precision: 2 decimal points | |||

--min/max: 0/5 | |||

--Units: "Volts" | |||

avgId = addChannel("SensorAvg", 10, 2, 0, 5, "Volts") | |||

function onTick() | |||

local a1 = getChannel("ch1") | |||

local a2 = getChannel("ch2") | |||

setChannel(avgId, (a1 + a2) / 2) | |||

end | |||

</pre> | |||

==Gear Calculation== | |||

Calculate gear position based on drive train ratios, RPM channel and gear. | |||

''Requires firmware 2.5.0'' | |||

Edit the gear ratios to match your vehicle. Assumes Speed is available on "Speed" channel, RPM is available on "RPM" channel. | |||

More details under the [[RaceCapturePro_Lua_Scripting#calcGear.28.29|calcGear API documentation]]. | |||

<pre> | |||

setTickRate(30) | |||

--create gear channel | |||

gearId = addChannel("Gear", 10, 0, 0, 6) | |||

function onTick() | |||

-- calculate gear: tire diameter(cm), final gear ratio, individual gear ratios 1-6 | |||

local gear = calcGear(62.7, 3.45, 4.23, 2.52, 1.66, 1.22, 1.0, 0.8) | |||

if gear == nil then gear = 0 end | |||

setChannel(gearId,gear) | |||

end | |||

</pre> | |||

''Also available as a preset'' | |||

==Throttle Position Calculation== | |||

Estimate throttle position based on G-Forces. 0-100% | |||

<pre> | |||

--Developed by Scott Barton of ProFormance Coaching for use by Autosport Labs Community | |||

MaxAccelG = 0.30 -- Look at your logs and see what your max acceleration is in 3rd or 4th gear. Note that full acceleration in 5th will not show 100% throttle. | |||

chThrottle = addChannel("vThrottle", 10, 0, 0, 100,'') | |||

function updatevThrottle() | |||

--AccelG = getChannel(LongAccel) --2.13 Firmware and up | |||

AccelG = getImu(0) --Prior to 2.13 Firmware | |||

TPS = (AccelG/MaxAccelG)*100 | |||

if TPS < 0 then TPS = 0 end | |||

TPS = math.abs(TPS) | |||

if TPS > 99 then TPS = 100 end | |||

setChannel(chThrottle, TPS) | |||

end | |||

--10Hz update | |||

setTickRate(10) | |||

function onTick() | |||

updatevThrottle() | |||

end | |||

</pre> | |||

==Brake Position Calculation== | |||

Estimate brake pedal position based on G-Forces. 0-100%. | |||

<pre> | |||

--Developed by Scott Barton of ProFormance Coaching for use by Autosport Labs Community | |||

MaxDecelG = 1.20 --Look at your logs and see what your maximum g-forces under straight line braking is and round down. | |||

chBrake = addChannel("vBrake", 10, 0, 0, 100, '') | |||

function updatevBrake() | |||

--BrakeG = getChannel(LongAccel) -- 2.13 Firmware and up | |||

BrakeG = getImu(0) --Prior to 2.13 Firmware | |||

--if ReverseAccel then | |||

BrakeG = BrakeG *-1 | |||

--BrakeG = -1.1 | |||

BrakePos = (BrakeG/MaxDecelG)*100 | |||

if BrakePos < 10 then BrakePos = 0 end | |||

BrakePos = math.abs(BrakePos) | |||

if BrakePos > 99 then BrakePos=100 end | |||

setChannel(chBrake, BrakePos) | |||

end | |||

--10Hz update | |||

setTickRate(10) | |||

function onTick() | |||

updatevBrake() | |||

end | |||

</pre> | |||

==Max RPM detection with GPIO reset== | |||

This script detects the peak RPM detected and stores it in a virtual channel. A GPIO is used to reset the channel to zero via a push button. | |||

<pre> | |||

maxRpmId = addChannel("MaxRPM", 10) | |||

maxRpm = 0 | |||

function rpmReset() | |||

local rpm = getTimerRpm(0) | |||

local clear = getGpio(0) | |||

if rpm > maxRpm then | |||

maxRpm = rpm | |||

setChannel(maxRpmId, maxRpm) | |||

end | |||

if clear == 0 then | |||

maxRpm = 0 | |||

setChannel(maxRpmId, maxRpm) | |||

end | |||

end | |||

function onTick() | |||

rpmReset() | |||

end | |||

</pre> | |||

=Alerts/Notifications= | |||

==Create an over-rev marker== | |||

This script will mark the datalog with an over-rev alert marker whenever RPMs are above a certain threshold. It will insert the current lap number to the OverRev channel. If multiple occurrences happen, you can take a look the event summary page and then look at each of those lap to see where and when it happened. | |||

Given: | |||

* RPM is connected a timer channel called RPM | |||

* RPM over-rev condition is 8000 | |||

<pre> | |||

setTickRate(10) | |||

overRevId = addChannel("OverRev", 10) | |||

function onTick() | |||

local rpm = getChannel("RPM") | |||

if rpm ~= nil and rpm > 8000 then | |||

setChannel(overRevId, getLapCount()) | |||

end | |||

</pre> | |||

==Create an Impact marker== | |||

This script will mark the datalog with an impact occurs (very high G-Forces). It will insert the current lap number to the Impact channel. If multiple occurrences happen, you can take a look the event summary page and then look at each of those lap to see where and when it happened. | |||

<pre> | |||

setTickRate(10) | |||

impactId = addChannel("Impact", 10) | |||

function onTick() | |||

local gsum = getChannel("Gsum") | |||

if gsum ~= nil and gsum > 2.0 then --Assumes anything over 2.0G's is an impact. Change to suit your needs. | |||

setChannel(impactId, getLapCount()) | |||

end | |||

end | |||

</pre> | |||

==Control a Fan or Pump switch based on Temp== | |||

<pre> | |||

function updateDiffSwitch() | |||

local diffTemp = getChannel("DiffTemp") --Change to your temperature channel name | |||

if diffTemp ~=nil and diffTemp > 180 then --update temp to turn on at | |||

setGpio(2,1) | |||

elseif diffTemp ~=nil and diffTemp < 160 then --update temp to turn off at | |||

setGpio(2,0) --Uses GPIO3 for output. Increase SampleRate or TickRate if it isn't turning on | |||

end | |||

end | |||

</pre> | |||

==Alert driver via electro-shock if oil pressure below safe threshold== | |||

This will alert driver via a shock (using pet scat mat) if oil pressure drops below threshold while engine is running above certain RPM | |||

[[Image:scat_mat_box.jpg]] | |||

Script will check at 10Hz (10 times/sec) for threshold condition | |||

Given: | |||

* Oil pressure on analog channel 0, and calibrated | |||

* Seat mounted pet scat mat installed in seat and controlled by GPIO 0 (GPIO switches ground when active) | |||

* GPIO 0 is configured for output mode | |||

* RPM is connected to timer input 0 | |||

<pre> | |||

--onTick() is called at 10Hz | |||

setTickRate(10) | |||

rpmThreshold = 2000 | |||

lowOilPressure = 15 | |||

function onTick() | |||

local shockDriver = 0 | |||

if getTimerRpm(0) > rpmThreshold and getAnalog(0) < lowOilPressure then | |||

shockDriver = 1 | |||

end | |||

setGpio(0, shockDriver) | |||

end | |||

</pre> | |||

==Track Max RPM / Value== | |||

This script will track a channel's maximum value and set a new channel with that maximum. | |||

Given: | |||

* RPM is connected to the first Timer input channel | |||

setTickRate(10) | |||

maxRpmId = addChannel("MaxRPM", 10) | |||

maxRpm = 0 | |||

function onTick() | |||

local rpm = getTimerRpm(0) | |||

if rpm > maxRpm then | |||

maxRpm = rpm | |||

setChannel(maxRpmId, maxRpm) | |||

end | |||

end | end | ||

| Line 69: | Line 643: | ||

More information: [[RaceCapturePro_installation_guide|Installation Guide]], [[RaceCapturePro_Sensors|Sensor Guide]], [[RaceCapturePro_SoftwareOperation|Operation Guide]] | More information: [[RaceCapturePro_installation_guide|Installation Guide]], [[RaceCapturePro_Sensors|Sensor Guide]], [[RaceCapturePro_SoftwareOperation|Operation Guide]] | ||

<pre> | |||

function onTick() | |||

if getAnalog(0) > 212 then | |||

setGpio(0, 1) | |||

else | |||

setGpio(0, 0) | |||

end | |||

end | |||

</pre> | |||

==Multi warning light== | |||

A script to trigger a warning light if at least one condition occurs. This will activate the output if the engine temperature is greater than 212 or if oil pressure drops below 10. | |||

* '''Note''' Actual temperature and pressure sensors must be connected to the appropriate analog inputs and correctly calibrated. | |||

<pre> | |||

--Analog 0 is engine temp, in degrees F | |||

--Analog 1 is oil pressure, in PSI | |||

function onTick() | |||

if getAnalog(0) > 212 or getAnalog(1) < 10 then | |||

setGpio(0, 1) | |||

else | |||

setGpio(0, 0) | |||

end | end | ||

end | |||

</pre> | |||

==Enable an LED if fuel level drops below 10%== | ==Enable an LED if fuel level drops below 10%== | ||

* '''Using PWM/Analog output''' | |||

* Using PWM/Analog output | ''only available on RaceCapture/Pro MK1 and MK2'' | ||

** Fuel sensor is on Analog 0, scaled 0-100% | ** Fuel sensor is on Analog 0, scaled 0-100% | ||

** LED indicator connected to PWM 0. When fuel level drops below 10%, Analog/PWM output 0 will show 5v; 0v if fuel level is higher | ** LED indicator connected to PWM 0. When fuel level drops below 10%, Analog/PWM output 0 will show 5v; 0v if fuel level is higher | ||

| Line 87: | Line 679: | ||

local p = 0 | local p = 0 | ||

if getAnalog(0) < 10 then p = 100 end | if getAnalog(0) < 10 then p = 100 end | ||

setPwmDutyCycle(0,p) | |||

end | end | ||

* Using GPIO | * '''Using GPIO in output mode''' | ||

** When fuel level drops below 10%, the GPIO is activated (output is grounded). Can be used to drive a relay or other device up to 1A load | ** When fuel level drops below 10%, the GPIO is activated (output is grounded). Can be used to drive a relay or other device up to 1A load | ||

** GPIO jumper set to output mode | |||

** GPIO setting in firmware set to match jumper setting | |||

function onTick() | function onTick() | ||

| Line 104: | Line 698: | ||

Given: | Given: | ||

* RPM sensor on timer input 0 | * RPM sensor on timer input 0 | ||

* GPIO channels are configured in output mode under '''Setup/GPIO''' | |||

| Line 114: | Line 709: | ||

if r > 7000 then setGpio(0,1) else setGpio(0,0) end | if r > 7000 then setGpio(0,1) else setGpio(0,0) end | ||

end | end | ||

==ProFormance Meter== | |||

Uses ShiftX to show you how much available grip you are using and how much is left. It also creates and updates the ProFormace channel which is an integer from 0-9. Closer to 9 you are the closer you are to max available grip. | |||

Instead of just using GSum, this takes into account that your MaxLatG's will be different than your MaxLongG's and gives you a more accurate representation of what you can do based on whether you are braking, turning, or accelerating. | |||

It also has 2 different models. 1) for an Advanced Driver and 2) for a Pro Driver. This is based on typical friction circles of Advanced Drivers vs Pro Drivers respectively. See the OnTick funtion to change DriverLevel. | |||

It also has an Oversteer Alert feature for ShiftX. Change the YawThreshold value to suit your needs. | |||

<pre> | |||

setTickRate(25) | |||

sxSetConfig(1) | |||

yawThreshold = 25 --At what yaw rate do you want the oversteer alarm lights to trigger' Check normal max yaw on your Podium.live race summaries to get a better idea of what value you should use | |||

maxGsumId = addChannel("MaxGsum", 25, 2, -2.0, 2.0) | |||

pctGsumMaxId = addChannel("PctMaxGsum", 25, 0, 0, 100) | |||

maxLatGId = addChannel("MaxLatG", 25, 2, -2.0, 2.0) | |||

maxBrakeGId = addChannel("MaxBrakeG", 25, 2, -2.0, 2.0) | |||

maxAccelGId = addChannel("MaxAccelG", 25, 2, -2.0, 2.0) | |||

ProFormanceRatingId = addChannel("ProFormance", 25, 0, 9) | |||

maxGsum = .3 | |||

maxLatG = .2 | |||

maxBrakeG = .2 | |||

maxAccelG = .1 | |||

currLatG = 0 | |||

longG = 0 | |||

lastLongG = 0 | |||

lastLatG = 0 | |||

function updateGStats() | |||

local gsum = getChannel("Gsum") | |||

if gsum ~= nil and gsum > 0 then | |||

if gsum > maxGsum then | |||

maxGsum = gsum | |||

setChannel(maxGsumId, maxGsum) | |||

end | |||

setChannel(pctGsumMaxId, (gsum / maxGsum) * 100) | |||

end | |||

local latG = getChannel("AccelY") | |||

if latG ~= nil then | |||

latG = math.abs(latG) | |||

if latG > maxLatG then | |||

maxLatG = latG | |||

setChannel(maxLatGId, maxLatG) | |||

end | |||

end | |||

local currLongG = getChannel("AccelX") | |||

if currLongG ~= nil then | |||

if currLongG>0 then | |||

if currLongG > maxBrakeG then | |||

maxBrakeG = currLongG | |||

setChannel(maxBrakeGId, maxBrakeG) | |||

end | |||

elseif currLongG<0 then | |||

currLongG = math.abs(currLongG) | |||

if currLongG>maxAccelG then | |||

maxAccelG = currLongG | |||

setChannel(maxAccelGId, maxAccelG) | |||

end | |||

end | |||

end | |||

end | |||

function alertYaw(Yaw) --Light up the side ShiftX lights in case of an Oversteer event | |||

if Yaw >= yawThreshold+20 then | |||

sxSetLed(7,2,255,255,255,9) | |||

elseif Yaw >= yawThreshold+10 then | |||

sxSetLed(7,2,255,255,255,5) | |||

elseif Yaw >= yawThreshold then | |||

sxSetLed(7,2,255,255,255,3) | |||

else | |||

sxSetLed(7,2,0,0,0,0) | |||

end | |||

end | |||

function resetSxLeds() --resets all the ShiftX lights to off | |||

sxSetLed(0,0,0,0,0,0) | |||

end | |||

function getProFormanceRating(driverLevel) --Calculate how much grip they are using and how much is left | |||

--driverLevel: 1=Advanced, 2=Pro | |||

local cLatG = getChannel("AccelY") | |||

if cLatG ~= nil then currLatG = math.abs(cLatG) end | |||

local cLongG = getChannel("AccelX") | |||

if cLongG ~= nil then | |||

longG = cLongG | |||

end | |||

local BrakeAccel = "Braking" | |||

local maxLongG = maxBrakeG | |||

--may not want to do this | |||

--if longG <= -0.01 then --Calculate Accel G's seperate from Braking G's | |||

-- BrakeAccel = "Accelerating" | |||

-- maxLongG = maxAccelG | |||

--end | |||

local currLongG = math.abs(longG) | |||

local latGAvail = 0 | |||

local longGAvail = 0 | |||

if driverLevel==1 then --Advanced driver | |||

latGAvail = maxLatG*(1-(currLongG/maxLongG)) | |||

longGAvail = maxLongG*(1-(currLatG/maxLatG)) | |||

else --Pro Driver | |||

latGAvail = math.sqrt(((maxLatG - ((maxLatG-maxLongG)*(currLongG/maxLongG)))^2)-(currLongG^2)) | |||

longGAvail = math.sqrt(((maxLongG - ((maxLongG-maxLatG)*(currLatG/maxLatG)))^2)-(currLatG^2)) | |||

end | |||

local percGUsedLat | |||

if latGAvail <= 0 then | |||

percGUsedLat = 1 | |||

else | |||

percGUsedLat = currLatG/latGAvail | |||

end | |||

local percGUsedLong | |||

if longGAvail <= 0 then | |||

percGUsedLong = 1 | |||

else | |||

percGUsedLong = currLongG/longGAvail | |||

end | |||

local ProFormanceRating | |||

if currLongG-lastLongG > currLatG-lastLatG then | |||

local TotalPot2 | |||

if (math.sqrt((currLatG^2)+(longGAvail^2))) <= 0 then | |||

TotalPot2 = 1 | |||

else | |||

TotalPot2 = (math.sqrt((currLatG^2)+(currLongG^2)))/(math.sqrt((currLatG^2)+(longGAvail^2))) | |||

end | |||

local TotalPot3 | |||

if (currLatG+longGAvail) <= 0 then | |||

TotalPot3 = 1 | |||

else | |||

TotalPot3 = (currLatG+currLongG)/(currLatG+longGAvail) | |||

end | |||

local avgTotPot = (((percGUsedLat+((1-(currLatG/maxLatG))*percGUsedLong))*2)+TotalPot2+TotalPot3)/4 | |||

ProFormanceRating = math.floor(avgTotPot*10) | |||

else | |||

local TotalPot2 | |||

if (math.sqrt((currLongG^2)+(latGAvail^2))) <= 0 then | |||

TotalPot2 = 1 | |||

else | |||

TotalPot2 = (math.sqrt((currLatG^2)+(currLongG^2)))/(math.sqrt((currLongG^2)+(latGAvail^2))) | |||

end | |||

local TotalPot3 | |||

if (currLongG+latGAvail) <= 0 then | |||

TotalPot3 = 1 | |||

else | |||

TotalPot3 = (currLatG+currLongG)/(currLongG+latGAvail) | |||

end | |||

local avgTotPot = (((percGUsedLong+((1-(currLongG/maxLongG))*percGUsedLat))*2)+TotalPot2+TotalPot3)/4 | |||

ProFormanceRating = math.floor(avgTotPot*10) | |||

end | |||

if ProFormanceRating<0 then ProFormanceRating=0 end | |||

if ProFormanceRating>9 then ProFormanceRating=9 end | |||

setChannel(ProFormanceRatingId, ProFormanceRating) | |||

lastLongG = currLongG | |||

lastLatG = currLatG | |||

return ProFormanceRating | |||

end | |||

function showProFormanceSx(rating) --Show ProFormanceRating on ShiftX | |||

local numLeds=7 --How many LEDs on the ShiftX do you want to use for the ProFormance meter. Default is 7; the 7 in the middle | |||

resetSxLeds() | |||

sxSetLed(0,numLeds,255,0,0,0) | |||

local percLeds = (.1*rating*(numLeds+1)) | |||

local greenLeds =math.floor(percLeds) | |||

if greenLeds>0 then sxSetLed(0,greenLeds,0,255,0,0) end | |||

if percLeds-greenLeds>0.61 then | |||

sxSetLed(greenLeds,1,100,100,0,2) | |||

end | |||

sxSetDisplay(0,rating) | |||

end | |||

function onTick() | |||

resetSxLeds() | |||

updateGStats() | |||

--ProFormance driver level: 1=Advanced, 2=Pro | |||

local driverLevel = 1 | |||

local ProFormanceRating = getProFormanceRating(driverLevel) | |||

showProFormanceSx(ProFormanceRating)--Show ProFormance Rating on ShiftX | |||

if getChannel("Yaw")~=nil then Yaw = getChannel("Yaw") end | |||

if math.abs(Yaw)>yawThreshold-5 then alertYaw(math.abs(Yaw)) end | |||

collectgarbage() | |||

end | |||

</pre> | |||

=CAN bus scripts= | |||

==Receive a CAN message on one bus and re-transmit on a different bus== | |||

setTickRate(30) | |||

function onTick() | |||

id, ext, data = rxCAN(0) | |||

if (id ~= nil) then | |||

txCAN(1, id, ext, data) | |||

end | |||

end | |||

==Send A CAN message with current GPS speed== | |||

Given: | |||

* Destination CAN device is looking for a message with ID 1234 | |||

* Standard (11 bit) CAN identifer | |||

* CAN1 channel is used | |||

function onTick() | |||

local speed = getGpsSpeed() | |||

--format the speed in a CAN message. Speed is in the first byte | |||

local msg = {speed} | |||

txCAN(0, 1234, 0, msg) | |||

end | |||

==Send A CAN message with a temperature value== | ==Send A CAN message with a temperature value== | ||

| Line 122: | Line 946: | ||

* Destination CAN device is looking for a message with ID 1234 | * Destination CAN device is looking for a message with ID 1234 | ||

* Standard (11 bit) CAN identifer | * Standard (11 bit) CAN identifer | ||

* CAN1 channel is used | |||

function onTick() | function onTick() | ||

local tmp = getAnalog(0) | |||

msg = { | local msg = {tmp} | ||

txCAN(1234, 0, msg) | txCAN(0, 1234, 0, msg) | ||

end | end | ||

==Use RCP as a general purpose CAN data logger== | |||

The following script will output any received CAN bus message to the log window. | |||

* You can access the log window by enabling polling in the script window under the RaceCapture app configuration view | |||

* You can also access the log window by connecting to RaceCapture/Pro from a terminal program (hyperterminal, Minicom, etc) and issuing the command: viewLog | |||

<pre> | |||

setTickRate(30) --30Hz | |||

function onTick() | |||

repeat --will drain CAN buffer on each tick | |||

id, e, data = rxCAN(0) | |||

if id ~= nil then | |||

print(id ..':') | |||

for i=1,#data do | |||

print(data[i] ..' ') | |||

end | |||

println('') | |||

end | |||

until id == nil | |||

end | |||

</pre> | |||

==Receive a CAN message and set a virtual channel== | ==Receive a CAN message and set a virtual channel== | ||

Given: | Given: | ||

* creates a channel named " | |||

* creates a channel named "MyChannel" that logs at 10Hz | |||

* Sets tick rate to 10Hz | * Sets tick rate to 10Hz | ||

* Receive a CAN message, with 100ms timeout | * Receive a CAN message on CAN1 channel, with 100ms timeout | ||

* if data received is valid (by checking the CAN message ID is not nil), then set the virtual channel with the first element in the CAN message data | * if data received is valid (by checking the CAN message ID is not nil), then set the virtual channel with the first element in the CAN message data | ||

channelId = addChannel("MyChannel", 10) | |||

setTickRate(10) | setTickRate(10) | ||

function onTick() | function onTick() | ||

id, ext, data = rxCAN(100) | id, ext, data = rxCAN(0, 100) | ||

if id ~= nil then | if id ~= nil then | ||

setChannel( | setChannel(channelId, data[1]) | ||

end | end | ||

end | end | ||

'''Note''': To map real CAN bus data, consult your CAN bus protocol documentation for correctly mapping CAN bus data to virtual channels. | |||

==CAN bus loopback test== | |||

Use This script to test functionality of your CAN bus. | |||

===Wiring / Setup === | |||

* Connect CAN1 high -> CAN2 high and CAN1 low -> CAN2 low. This can either be done though the main wiring harness or the RJ45 connector. | |||

** '''Note''' if your unit has CAN on the wiring harness and the RJ45 connector, you only need to bridge the connections on one harness, since they are internally wired together. | |||

* Set the CAN baud rates to the same value for CAN1 and CAN 2. | |||

[[image:CAN_loopback_test.png]] | |||

<pre> | |||

-- CAN loopback test | |||

-- * Wire CAN1 high -> CAN2 high and CAN 1 low -> CAN 2 low | |||

-- * Ensure baud rate is identical for both CAN1 and CAN2 | |||

can_id = 1234 | |||

count = 0 | |||

function onTick() | |||

count = count + 1 | |||

-- transmit a CAN message on CAN1 with count as the first byte | |||

local tx_result = txCAN(0, can_id, 0, {count}) | |||

println('transmit result ' ..tx_result) | |||

-- receive a CAN message on CAN2 | |||

local id, ext, data = rxCAN(1) | |||

if id == nil then | |||

println('No CAN message received!') | |||

else | |||

println('Got CAN message ID: ' ..id ..' data: ' ..data[1]) | |||

end | |||

end | |||

</pre> | |||

==Integrate with RaceVoice via CAN== | |||

[https://www.racevoice.com/ RaceVoice] integrates with your data logger to audibly tell you info like high engine temp, low oil pressure, overrev, low battery, wheel lockup warnings as well as Pit to Car messages and soon Timing and Scoring data. It can also tell you things like rolling MPH at the end of a straight, max g-forces through a turn, lap segment delta, lap times, etc in order to be a more consistent and faster driver. | |||

You can find a list of [https://www.racevoice.com/features/ Race Voice Features here]. | |||

Take a look at this video for more info. | |||

{{#evu:https://www.youtube.com/watch?v=9aWVu1JyiZo}} | |||

''Please note that [https://podium.live/software Firmware 2.18] or greater is required for the Pit to Car messaging to work with RaceVoice.'' | |||

''Please look at the RCP channel names in the getChannel('ChannelName') functions below and make sure that your channel names match. If you aren't using a channel, don't worry about it. But if you are using a channel but it is named differently in your configuration, please either rename it in your config or rename it in the script below so that they match.'' | |||

<pre> | |||

--Created by Scott Barton of ProFormance Coaching for Autosport Labs Community | |||

tickRate = 10 | |||

setTickRate(tickRate) | |||

TPS = 100 | |||

RPM = 0 | |||

Speed = 0 | |||

AccelY = 0 | |||

AccelX = 0 | |||

ECT = 0 | |||

OilP = 0 | |||

Volts = 0 | |||

BrakeP = 0 | |||

WheelSpdLF = 0 | |||

WheelSpdRF = 0 | |||

WheelSpdLR = 0 | |||

WheelSpdRR = 0 | |||

LapNum = 0 | |||

LapTime = 0 | |||

BestTime = 0 | |||

LapDelta = 0 | |||

Lat = 0 | |||

Long = 0 | |||

function toDec(msg, char) | |||

if string.byte (msg, char) == nil then | |||

return 0 | |||

else | |||

return string.byte (msg, char) | |||

end | |||

end | |||

function txRVMessage(msg, channel) | |||

txCAN(channel, 0xA100, 1, {toDec(msg, 1), toDec(msg, 2), toDec(msg, 3), toDec(msg, 4), toDec(msg, 5), toDec(msg, 6), toDec(msg, 7), toDec(msg, 8)}) | |||

txCAN(channel, 0xA101, 1, {toDec(msg, 9), toDec(msg, 10), toDec(msg, 11), toDec(msg, 12), toDec(msg, 13), toDec(msg, 14), toDec(msg, 15), toDec(msg, 16)}) | |||

end | |||

function split16(val) | |||

return bit.band(val, 0xFF), bit.band(bit.rshift(val,8), 0xFF) | |||

end | |||

function split32(val) | |||

return bit.band(val, 0xFF), bit.band(bit.rshift(val,8), 0xFF), bit.band(bit.rshift(val,16),0xFF),bit.band(bit.rshift(val,24),0xFF) | |||

end | |||

function txRVCANData(channel) | |||

local lTPS = getChannel('TPS') | |||

if lTPS ~= nil then TPS = lTPS end | |||

local TPS1, TPS2 = split16(TPS) | |||

local lRPM = getChannel('RPM') | |||

if lRPM ~= nil then RPM = lRPM end | |||

local RPM1, RPM2 = split16(RPM) | |||

local lSpeed = getChannel('Speed') | |||

if lSpeed ~= nil then Speed = lSpeed end | |||

local Speed1, Speed2 = split16(Speed) | |||

local lAccelX = getChannel('AccelX') | |||

if lAccelX ~= nil then AccelX = lAccelX end | |||

local AccelX1, AccelX2 = split16(AccelX*100) | |||

local lAccelY = getChannel('AccelY') | |||

if lAccelY ~= nil then AccelY = lAccelY end | |||

local AccelY1, AccelY2 = split16(AccelY*100) | |||

local lECT = getChannel('EngineTemp') | |||

if lECT ~= nil then ECT = lECT end | |||

local ECT1, ECT2 = split16(ECT) | |||

local lOilP = getChannel('OilPress') | |||

if lOilP ~= nil then OilP = lOilP end | |||

local OilP1, OilP2 = split16(OilP) | |||

local lVolts = getChannel('Battery') | |||

if lVolts ~= nil then Volts = lVolts end | |||

local Volts1, Volts2 = split16(Volts*10) | |||

local lBrakeP = getChannel('BrakeF') | |||

if lBrakeP ~= nil then BrakeP = lBrakeP end | |||

local BrakeP1, BrakeP2 = split16(BrakeP) | |||

local lWheelSpdLF = getChannel('WhlSpeedLF') | |||

if lWheelSpdLF ~= nil then WheelSpdLF = lWheelSpdLF end | |||

local WheelSpdLF1, WheelSpdLF2 = split16(WheelSpdLF) | |||

local lWheelSpdRF = getChannel('WhlSpeedRF') | |||

if lWheelSpdRF ~= nil then WheelSpdRF = lWheelSpdRF end | |||

local WheelSpdRF1, WheelSpdRF2 = split16(WheelSpdRF) | |||

local lWheelSpdLR = getChannel('WhlSpeedLR') | |||

if lWheelSpdLR ~= nil then WheelSpdLR = lWheelSpdLR end | |||

local WheelSpdLR1, WheelSpdLR2 = split16(WheelSpdLR) | |||

local lWheelSpdRR = getChannel('WhlSpeedRR') | |||

if lWheelSpdRR ~= nil then WheelSpdRR = lWheelSpdRR end | |||

local WheelSpdRR1, WheelSpdRR2 = split16(WheelSpdRR) | |||

local lLapNum = getChannel('CurrrentLap') | |||

if lLapNum ~= nil then LapNum = lLapNum end | |||

local LapNum1, LapNum2 = split16(LapNum) | |||

local lLapTime = getChannel('LapTime') | |||

if lLapTime ~= nil then LapTime = lLapTime end | |||

local LapTime1, LapTime2 = split16(LapTime*10000) | |||

local lBestTime = getChannel('Bestlap') | |||

if lBestTime ~= nil then BestTime = lBestTime end | |||

local BestTime1, BestTime2 = split16(BestTime*10000) | |||

local lLapDelta = getChannel('LapDelta') | |||

if lLapDelta ~= nil then LapDelta = lLapDelta end | |||

local LapDelt11, LapDelta2 = split16(LapDelta*1000) | |||

local lLat = getChannel('Latitude') | |||

if lLat ~= nil then Lat = lLat end | |||

local Lat1, Lat2, Lat3, Lat4 = split32(Lat*10000000) | |||

local lLong = getChannel('Longitude') | |||

if lLong ~= nil then Long = lLong end | |||

local Long1, Long2, Long3, Long4 = split32(Long*10000000) | |||

txCAN(channel, 0x50, 0, {TPS2, TPS1, RPM2, RPM1, Speed2, Speed1, BrakeP2, BrakeP1}) | |||

txCAN(channel, 0x53, 0, {AccelX2, AccelX1, AccelY2, AccelY1}) | |||

txCAN(channel, 0x55, 0, {ECT2, ECT1, OilP2, OilP1, Volts2, Volts1}) | |||

txCAN(channel, 0x5A, 0, {LapNum2, LapNum1, LapTime2, LapTime1, BestTime2, BestTime1, LapDelta2, LapDelta1}) | |||

txCAN(channel, 0x56, 0, {Lat4, Lat3, Lat2, Lat1, Long4, Long3, Long2, Long1}) | |||

txCAN(channel, 0x51, 0, {WheelSpdLF2, WheelSpdLF1, WheelSpdRF2, WheelSpdRF1, WheelSpdLR2, WheelSpdLR1, WheelSpdRR2, WheelSpdRR1}) | |||

end | |||

counter = 0 | |||

function onTick() | |||

canChannel = 0 --0=CANChannel1; 1=CANChannel2 | |||

txRVCANData(canChannel) | |||

counter = counter+1 | |||

if counter > 300 then --Change this section to send custom messages to RaceVoice | |||

counter = 0 | |||

txRVMessage("Hello World!", canChannel) | |||

end | |||

collectgarbage() | |||

end | |||

</pre> | |||

''Be sure to change the this section in the onTick() function so that it sends your custom message to RaceVoice that you want under the conditions you want. Ie. Low tire pressures, etc. '' | |||

<pre> if counter > 300 then --Change this section to send custom messages to RaceVoice | |||

counter = 0 | |||

txRVMessage("Hello World!", canChannel) | |||

end | |||

</pre> | |||

''otherwise it will just keep saying Hello World! every 30 seconds. Delete that section if you don't want to send custom alerts or messages to RaceVoice.'' | |||

''Note: the custom message is limited to 16 characters. Only the first 16 characters will be spoken. You can send multiple messages if needed.'' | |||

==Spoof AIM data logger in order to use AIM SmartyCam alone with Race Capture == | |||

If you want to add video with automatic data overlay, you can use an [https://www.bimmerworld.com/AiM-SmartyCam-HD-Camera-System-84-Deg-Lens.html AIM SmartyCam]. Normally this has to be connected to an AIM data logging system in order for it to get the data to overlay onto the video. | |||

We will use the CAN transmit ability of the Race Capture devices to spoof an AIM data logger and send our RCP sensor data (or RCT OBDII data) over to the AIM SmartyCam. | |||

Note: For the AIM SmartyCAM HD Rev 1 with 5 pin connector you will just need an [https://www.autosportlabs.com/product/aim-dashboard-telemetry-cable/ ASL AIM to RCP cable]. If you have an original AIM SmartyCam or SmartyCam HD Rev 2 which have 7 pin connectors, you will also need an [https://www.bimmerworld.com/AiM-4-Way-Data-Hub.html AIM Data Hub]. You will plug your 7 pin to 5 pin cable you got with your original SmartyCam or SmartyCam HDrev2 into your SmartyCam and the other end (5 pin end) into the AIM Data Hub. You would then plug your ASL AIM to RCP cable into the RCP and the AIM Data Hub. | |||

These will communicate on CAN Channel 1 with a baud rate of 1M. Make those settings in the CAN Bus settings. | |||

<pre> | |||

--Created by Scott Barton of ProFormance Coaching for Autosport Labs Community | |||

tickRate = 10 | |||

setTickRate(tickRate) | |||

TPS = 0 | |||

RPM = 0 | |||

Speed = 0 | |||

Gear = 0 | |||

AccelY = 0 | |||

AccelX = 0 | |||

ECT = 0 | |||

EGT = 0 | |||

Coolant = 0 | |||

OilT = 0 | |||

OilP = 0 | |||

Volts = 0 | |||

AFR = 0 | |||

Fuel = 0 | |||

Brake = 0 | |||

BrakeP = 0 | |||

Steering = 0 | |||

ClutchP = 0 | |||

Lat = 0 | |||

Long = 0 | |||

function split16(val) | |||

return bit.band(val, 0xFF), bit.band(bit.rshift(val,8), 0xFF) | |||

end | |||

function split32(val) | |||

return bit.band(val, 0xFF), bit.band(bit.rshift(val,8), 0xFF), bit.band(bit.rshift(val,16),0xFF),bit.band(bit.rshift(val,24),0xFF) | |||

end | |||

function txSCCANData(channel) | |||

local lTPS = getChannel('TPS') | |||

if lTPS ~= nil then TPS = lTPS end | |||

local TPS1, TPS2 = split16(TPS) | |||

local lRPM = getChannel('RPM') | |||

if lRPM ~= nil then RPM = lRPM end | |||

local RPM1, RPM2 = split16(RPM) | |||

local lSpeed = getChannel('Speed') | |||

if lSpeed ~= nil then Speed = lSpeed end | |||

local Speed1, Speed2 = split16(Speed) | |||

local lAccelX = getChannel('AccelX') | |||

if lAccelX ~= nil then AccelX = lAccelX end | |||

local AccelX1, AccelX2 = split16(AccelX*100) | |||

local lAccelY = getChannel('AccelY') | |||

if lAccelY ~= nil then AccelY = lAccelY end | |||

local AccelY1, AccelY2 = split16(AccelY*100) | |||

local lECT = getChannel('EngineTemp') | |||

if lECT ~= nil then ECT = lECT end | |||

local ECT1, ECT2 = split16(ECT) | |||

local lCoolant = getChannel('Coolant') | |||

if lCoolant ~= nil then Coolant = lCoolant end | |||

local Coolant1, Coolant2 = split16(Coolant) | |||

local lEGT = getChannel('EGT') | |||

if lEGT ~= nil then EGT = lEGT end | |||

local EGT1, EGT2 = split16(EGT) | |||

local lOilT = getChannel('OilTemp') | |||

if lOilT ~= nil then OilT = lOilT end | |||

local OilT1, OilT2 = split16(OilT) | |||

local lOilP = getChannel('OilPress') | |||

if lOilP ~= nil then OilP = lOilP end | |||

local OilP1, OilP2 = split16(OilP) | |||

local lFuel = getChannel('FuelLevel') | |||

if lFuel ~= nil then Fuel = lFuel end | |||

local Fuel1, Fuel2 = split16(Fuel) | |||

local lAFR = getChannel('AFR') | |||

if lAFR ~= nil then AFR = lAFR end | |||

local AFR1, AFR2 = split16(AFR) | |||

local lVolts = getChannel('Battery') | |||

if lVolts ~= nil then Volts = lVolts end | |||

local Volts1, Volts2 = split16(Volts*10) | |||

local lBrake = getChannel('Brake_F') | |||

if lBrake ~= nil then Brake = lBrake end | |||

local Brake1, Brake2 = split16(Brake) | |||

local lBrakeP = getChannel('Brake') | |||

if lBrakeP ~= nil then BrakeP = lBrakeP end | |||

local BrakeP1, BrakeP2 = split16(BrakeP) | |||

local lClutchP = getChannel('Clutch') | |||

if lClutchP ~= nil then ClutchP = lClutchP end | |||

local ClutchP1, ClutchP2 = split16(ClutchP) | |||

local lSteering = getChannel('Steering') | |||

if lSteering ~= nil then Steering = lSteering end | |||

local Steering1, Steering2 = split16(Steering) | |||

local lGear = getChannel('Gear') | |||

if lGear ~= nil then Gear = lGear end | |||

local Gear1, Gear2 = split16(Gear) | |||

local lLapNum = getChannel('CurrrentLap') | |||

if lLapNum ~= nil then LapNum = lLapNum end | |||

local LapNum1, LapNum2 = split16(LapNum) | |||

local lLapTime = getChannel('LapTime') | |||

if lLapTime ~= nil then LapTime = lLapTime end | |||

local LapTime1, LapTime2 = split16(LapTime*10000) | |||

local lBestTime = getChannel('Bestlap') | |||

if lBestTime ~= nil then BestTime = lBestTime end | |||

local BestTime1, BestTime2 = split16(BestTime*10000) | |||

local lLapDelta = getChannel('LapDelta') | |||

if lLapDelta ~= nil then LapDelta = lLapDelta end | |||

local LapDelt11, LapDelta2 = split16(LapDelta*1000) | |||

local lLat = getChannel('Latitude') | |||

if lLat ~= nil then Lat = lLat end | |||

local Lat1, Lat2, Lat3, Lat4 = split32(Lat*10000000) | |||

local lLong = getChannel('Longitude') | |||

if lLong ~= nil then Long = lLong end | |||

local Long1, Long2, Long3, Long4 = split32(Long*10000000) | |||

txCAN(channel, 40, 0, {0, Long1, Long2, Long3, Long4}) | |||

txCAN(channel, 40, 0, {1, Lat1, Lat2, Lat3, Lat4}) | |||

txCAN(channel, 1056, 0, {RPM1, RPM2, Speed1, Speed2, Gear1, Gear2, Coolant1, Coolant2}) | |||

txCAN(channel, 1057, 0, {ECT1, ECT2, EGT1, EGT2, OilT1, OilT2, OilP1, OilP2}) | |||

txCAN(channel, 1058, 0, {Brake1, Brake2, TPS1, TPS2, BrakeP1, BrakeP2, ClutchP1, ClutchP2}) | |||

txCAN(channel, 1059, 0, {Steering1, Steering2, AFR1, AFR2, AccelY1, AccelY2, AccelX1, AccelX2}) | |||

txCAN(channel, 1060, 0, {Fuel1, Fuel2, Volts1, Volts2}) | |||

end | |||

function onTick() | |||

txSCCANData(0) --0=CAN Channel 1; 1=CAN Channel 2 | |||

collectgarbage() | |||

end | |||

</pre> | |||

=Serial Port= | |||

==Read an analog sensor value and output it to the auxiliary serial port== | |||

This example reads an analog sensor and writes a string containing the value to the Auxiliary serial port. Repeats once per second. | |||

<pre> | |||

--initialize Aux serial port to 115200, 8, N, 1 | |||

initSer(4, 115200, 8, 0, 1) | |||

function onTick() | |||

value = getAnalog(0) | |||

writeSer(4, 'A=' ..value) | |||

end | |||

</pre> | |||

==Read a line of serial data== | |||

This example reads a line of serial data and writes it to the internal RaceCapture log. | |||

* '''Note''': You can monitor the log by enabling the log polling in the script configuration view. | |||

<pre> | |||

--initialize Aux serial port to 115200, 8, N, 1 | |||

initSer(4, 115200, 8, 0, 1) | |||

function onTick() | |||

--read a line from the aux serial port with a 100ms timeout | |||

value = readSer(4, 100) | |||

if value ~= nil then | |||

println('read value: ' ..value) | |||

end | |||

end | |||

</pre> | |||

=Demo Scripts= | |||

==RPM Sweep== | |||

This sweeps an RPM channel up and down through a pre-defined range. Edit the range at the top of the script. | |||

<pre> | |||

-- 05 Jan 2016 RPM demo | |||

-- F.Mirandola - B.Picasso | |||

-- This code will show a demo RPM sweep on RaceCapturePro | |||

thrRpmLo = 3000 | |||

--Low RPM threshold for change direction | |||

thrRpmHi = 10000 | |||

--Hi RPM threshold for change direction | |||

incrementRpm = 300 | |||

--Step between each RPM increment/decrement, will affect the speed, higher = faster | |||

-- Do not edit after this!! | |||

setTickRate(10) | |||

rpm = 0 | |||

direction = 0 | |||

rpmId = addChannel("RPM", 10, 0, 0, 10000) | |||

function onTick() | |||

setChannel(rpmId, rpm) | |||

if (rpm<=thrRpmHi and direction == 0 ) then rpm = rpm + incrementRpm | |||

elseif (rpm>=thrRpmLo and direction == 1 ) then rpm = rpm - incrementRpm | |||

end | |||

if (rpm>thrRpmHi) then direction = 1 | |||

elseif (rpm<thrRpmLo) then direction = 0 | |||

end | |||

end | |||

</pre> | |||

==Simulating Laps== | |||

Here's a neat script that can simulate lap times and predicted times. We've used it to develop dashboard features for the app. Especially interesting is the use of the accelerometer to generate a bit of noise and variability in the data. | |||

<pre> | |||

--Script to simulate lap and predicted times | |||

--Without needing a moving car on race track! | |||

--To use, disable Race Timing in RaceCapture/Pro configuration and | |||

--use this script | |||

etid = addChannel("ElapsedTime", 10, 4) | |||

ltid = addChannel("LapTime", 10, 4) | |||

ptid = addChannel("PredTime", 10, 4) | |||

clid = addChannel("CurrentLap", 10, 0) | |||

lcid = addChannel("LapCount", 10, 0) | |||

et = 0 --ElapsedTime value | |||

lt = 0 --LapTime value | |||

pt = 0 --PredTime value | |||

cl = 0 --CurrentLap value | |||

lc = 0 --LapCount value | |||

targetTime = 0.5 --target time for our fake laps | |||

setTickRate(10) | |||

function onTick() | |||

local rnd = getImu(0) --use the IMU to create a random-ish number | |||

--simulate a predicted time if we've already | |||

--completed a lap | |||

--rnd value makes the predicted time jiggle | |||

if lc > 0 then | |||

pt = targetTime + rnd | |||

setChannel(ptid, pt) | |||

end | |||

--increment elapsed time by 1/10 second | |||

et = et + 0.00166666667 | |||

setChannel(etid, et) | |||

if et > targetTime + rnd then | |||

lt = et | |||

setChannel(ltid, lt) | |||

et = 0 | |||

cl = cl + 1 | |||

setChannel(clid, cl) | |||

if cl > 1 then | |||

lc = lc + 1 | |||

setChannel(lcid, lc) | |||

end | |||

end | |||

end | |||

</pre> | |||

Latest revision as of 19:50, 25 January 2024

How to set a script in the RaceCapture app

HowTo video: set custom script

API Reference

OBDII tricks

Clear current trouble codes

This script clears any current trouble codes every 10 seconds. Clearing the code requires transmitting an OBDII command to ID 0x7DF with mode 4 specified. No other parameters are specified.

setTickRate(1)

count = 0

function onTick()

checkClearCodes()

end

function checkClearCodes()

if count % 10 == 0 then

print('clearing codes')

txCAN(0, 0x7df, 0, {1,4})

end

end

Query and Decode Diagnostic Trouble Code

This script queries for a DTC, and if found, prints the decoded trouble code and the raw data.

--This example queries for and reads the first available DTC, if present.

setTickRate(1)

--P=Powertrain, C=Chassis, B=Body, U=Network

prefixes = {'P','C','B','U'}

digits = {'0','1','2','3','4','5','6','7','8','9','A','B','C','D','E','F'}

function toDigit(v)

return digits[v+1]

end

function printDTC(data)

local dtc

local a = data[3]

local b = data[4]

local prefix = prefixes[bit.band(bit.rshift(a, 6), 0x03) + 1]

local c2 = bit.band(bit.rshift(a, 4), 0x03)

local c3 = bit.band(a, 0x0f)

local c4 = bit.band(bit.rshift(b, 4), 0x0F)

local c5 = bit.band(b, 0x0F)

local code = prefix ..toDigit(c2) ..toDigit(c3) ..toDigit(c4) ..toDigit(c5)

println('Found DTC: ' ..code)

end

function printRawDTC(data)

print('Raw DTC bytes: ')

--print the remaining 6 bytes,

--this raw data holds the trouble codes

for i=1, #data do print(' ' ..data[i]) end

println('')

end

function checkDTCResponse()

local attempts = 0

while attempts < 50 do

local id,ext, data = rxCAN(0, 10)

if id ~= nil and ext == 0 and id == 0x7e8 then

if data[2] == 0x43 then

if data[1] > 2 then

printRawDTC(data)

printDTC(data)

else

println('No DTC Found')

end

return

end

end

attempts = attempts + 1

end

end

function sendCheckDTC()

println('Sending check DTC')

txCAN(0, 0x7df, 0, {1,3})

end

function onTick()

sendCheckDTC()

checkDTCResponse()

end

Display OBDII Codes as a channel and allow driver to reset the OBDII Codes with a button

This script creates a virtual channel called OBDIICodes and sets it to the first OBDII Trouble Code found (It will not have the alpha prefix (Ie P, C , B, or U), but will just have up to 4 digits. You can then use these digits to figure out the P code. Ie, if 155 is returned, your OBDII code would be P0155. If -1 is shown for the OBDIICodes channel that means RaceCapture has not received any codes from the ECU yet. If 0 is shown for OBDIICodes channel that means the ECU sent back P0000 which means there are no OBDII trouble codes in the ECU. This channel will be logged and sent via telemetry just like a regular channel. If more than one OBDII code is found, it will cycle setting the OBDIICodes channel to the first 2-3 OBDII codes that were returned. It will cycle to the next code every couple of seconds.

I also added the ability for the driver to reset the OBDII Trouble codes using an external button. This button needs to be mapped to an Analog or GPIO channel called ClearOBD. It will reset the vehicle's OBDII codes and reset the OBDIICodes channel to -1.

Here is a video of the functionality in action.

--Modified by Scott Barton of ProFormance Coaching for Autosport Labs Community

tickRate = 5

setTickRate(tickRate)

counter=0

--P=Powertrain, C=Chassis, B=Body, U=Network

prefixes = {'P','C','B','U'}

digits = {'0','1','2','3','4','5','6','7','8','9','A','B','C','D','E','F'}

OBDCodes = {'-1'}

currCode = 1

addChannel("OBDIICodes", 1, 0)

setChannel("OBDIICodes", -1)-- Some car manufactures send P0000 if there are no fault codes; therefore we will use -1 to know that no codes have been returned yet

function clearOBDCodes()

for i=#OBDCodes, 1, -1 do

OBDCodes[i] = nil

end

OBDCodes[1] = '-1'

end

function addOBDCode(code)

local codeFound = false

for i=1, #OBDCodes do

if OBDCodes[i] == '-1' or OBDCodes[i] == 0 then OBDCodes[i] = nil end

if OBDCodes[i] == code then codeFound=true end

end

if not codeFound then

OBDCodes[#OBDCodes+1] = code

println(#OBDCodes ..' Total OBDII Codes Found So Far')

end

end

function displayOBDCodes()

counter = counter+1

if counter == 3*tickRate then --seconds since last update

currCode = currCode+1

if currCode>#OBDCodes then currCode=1 end

--println('Updating OBDII Code ' ..currCode ..' ' ..OBDCodes[currCode])

counter = 0

end

setChannel("OBDIICodes", OBDCodes[currCode])

end

function checkClearCodes(canChan)

local ClrOBD = getChannel("ClearOBD ") --Must create an analog or GPIO channel called ClearOBD in your settings and map it to read 1 or higher when you push the external button wired to that input

if ClrOBD ~= nil and ClrOBD > 0 then

println('Clearing OBDII codes')

txCAN(canChan, 0x7df, 0, {1,4}) --sends reset OBDII codes command to ECU

clearOBDCodes()

setChannel("OBDIICodes", -1)

end

end

function toDigit(v)

return digits[v+1]

end

function printDTC(data)

local dtc

local a = data[3]

local b = data[4]

local prefix = prefixes[bit.band(bit.rshift(a, 6), 0x03) + 1]

local c2 = bit.band(bit.rshift(a, 4), 0x03)

local c3 = bit.band(a, 0x0f)

local c4 = bit.band(bit.rshift(b, 4), 0x0F)

local c5 = bit.band(b, 0x0F)

local code = toDigit(c2) ..toDigit(c3) ..toDigit(c4) ..toDigit(c5)

addOBDCode(code)

--setChannel("OBDIICodes", code)

code = prefix ..code

println('Found DTC: ' ..code)

a = data[5]

b = data[6]

local d2 = bit.band(bit.rshift(a, 4), 0x03)

local d3 = bit.band(a, 0x0f)

local d4 = bit.band(bit.rshift(b, 4), 0x0F)

local d5 = bit.band(b, 0x0F)

local code2 = toDigit(d2) ..toDigit(d3) ..toDigit(d4) ..toDigit(d5)

if tonumber(code2) ~= nil and tonumber(code2)>1 then

addOBDCode(code2)

code2 = prefix ..code2

println('Found 2nd DTC: ' ..code2)

end

a = data[7]

b = data[8]

local e2 = bit.band(bit.rshift(a, 4), 0x03)

local e3 = bit.band(a, 0x0f)

local e4 = bit.band(bit.rshift(b, 4), 0x0F)

local e5 = bit.band(b, 0x0F)

local code3 = toDigit(e2) ..toDigit(e3) ..toDigit(e4) ..toDigit(e5)

if tonumber(code3) ~= nil and tonumber(code3)>1 then

addOBDCode(code3)

code3 = prefix ..code3

println('Found 3rd DTC: ' ..code3)

end

end

function printRawDTC(data)

print('Raw DTC bytes: ')

--print the remaining 6 bytes,

--this raw data holds the trouble codes

for i=1, #data do print(' ' ..data[i]) end

println('')

end

function checkDTCResponse(canChan)

local attempts = 0

while attempts < 50 do

local id,ext, data = rxCAN(canChan, 10)

if id ~= nil and ext == 0 and id == 0x7e8 then

if data[2] == 0x43 then

if data[1] > 2 then

printRawDTC(data)

printDTC(data)

else

--println('No DTC Found')

end

return

end

end

attempts = attempts + 1

end

end

function sendCheckDTC(canChan)

--println('Sending check DTC')

txCAN(canChan, 0x7df, 0, {1,3})

end

function onTick()

sendCheckDTC(1) --0=OBDII is on CAN Channel 1; 1=OBD is on CAN Channel 2

checkDTCResponse(1)

displayOBDCodes()

checkClearCodes(1)

end

Data filtering

Simple RPM Filter

Got a noisy RPM signal where big spikes show up? This will reject RPM values above a sane threshold.

Important - make sure the RPM channel in the main RaceCapture/Pro config is disabled, since this virtual channel replaces it.

--sample RPM at 10Hz

setTickRate(10)

--set this value to be your sane upper limit

rpmLimit = 10000

--In the RCP config, ensure the timer channels are disabled

--we will create the virtual channel here

rpmId = addChannel( "RPM", 10, 0, 0, rpmLimit)

rpm = 0

function doRPM()

local r = getTimerRpm(0)

if r < rpmLimit then

rpm = r

end

setChannel(rpmId, rpm)

end

function onTick()

doRPM()

end

Automatic logging control

Automatically Start Logging When Powered On

This script will automatically start logging the moment RaceCapture/Pro turns on

- Note, this will create a file with an incorrect timestamp if GPS lock is not established.

- To get a properly time-stamped file, use the GPS speed triggered approach.

function onTick() startLogging() end

Automatically Start Logging based on GPS Speed

This script will automatically start logging to SD card when speed exceeds 10MPH and stop when it falls below.

function onTick()

if getGpsSpeed() > 10 then

startLogging()

else

stopLogging()

end

end

Automatically Start Logging when engine is running

This script will automatically start logging to SD card when battery voltage shows that the engine is running

- When battery voltage is greater than 13 volts, we assume engine is running.

- System battery voltage is tied to the last Analog channel (8) (Note, change this to 7 if RaceCapture/Pro MK2)

function onTick()

if getAnalog(8) > 13 then

startLogging()

else

stopLogging()

end

end

Automatically start Logging upon Launch (AutoX / Rally / Hill Climb)

This script will start Logging when a dash mounted "ARM" switch is activated via an input and G-force exceeds a threshold Given:

- GPIO 0 configured as input and connected to dash mounted "Arm" switch

- Default RaceCapture/Pro mounting orientation (terminal block facing forward, mounted upright)

- G-force launch threshold is -0.1 G

- flipping the ARM switch to 'Off' will stop logging

setTickRate(30)

overRevId = addChannel("OverRev", 10)

function onTick()

local arm = getGpio(0)

local g = getAccel(1)

if arm == 0 then

stopLogging()

end

if arm == 1 and g < 0.1 then

startLogging()

end

end

Virtual Channels (AKA Math Channels)

Averaging a fuel level reading or other sensor

This script calculates a moving average to account for fuel slosh. Assumptions:

- Fuel level is connected to the first analog channel and is calibrated; modify the script to base the reading on other channels as appropriate.

--The real analog channel should be named

--something other than FuelLevel

fuel2Id = addChannel("FuelLevel", 10, 0, 0,100,"%")

--change this to make a bigger averaging window

maxAvg = 600

--600 = 20 seconds averaging at 30Hz tick rate

--do not change

fuelAvg={}

fuel2Index = 1

function updateFuelAvg(value)

local i

if #fuelAvg == 0 then

--initialize averaging table

for i = 1, maxAvg do fuelAvg[i]=0 end

end

fuelAvg[fuel2Index] = value

fuel2Index = fuel2Index + 1

if fuel2Index > maxAvg then fuel2Index = 1 end

local sum = 0

for i = 1, #fuelAvg do

sum = sum + fuelAvg[i]

end

setChannel(fuel2Id, sum / maxAvg)

end

setTickRate(30)

function onTick()

updateFuelAvg(getAnalog(0))

end

Average two sensor values and set to a virtual channel

--10Hz update

setTickRate(10)

--Create channel: "SensorAvg"

--Sample rate: 10Hz

--Logging precision: 2 decimal points

--min/max: 0/5

--Units: "Volts"

avgId = addChannel("SensorAvg", 10, 2, 0, 5, "Volts")

function onTick()

local a1 = getChannel("ch1")

local a2 = getChannel("ch2")

setChannel(avgId, (a1 + a2) / 2)

end

Gear Calculation

Calculate gear position based on drive train ratios, RPM channel and gear. Requires firmware 2.5.0

Edit the gear ratios to match your vehicle. Assumes Speed is available on "Speed" channel, RPM is available on "RPM" channel.

More details under the calcGear API documentation.

setTickRate(30)

--create gear channel

gearId = addChannel("Gear", 10, 0, 0, 6)

function onTick()

-- calculate gear: tire diameter(cm), final gear ratio, individual gear ratios 1-6

local gear = calcGear(62.7, 3.45, 4.23, 2.52, 1.66, 1.22, 1.0, 0.8)

if gear == nil then gear = 0 end

setChannel(gearId,gear)

end

Also available as a preset

Throttle Position Calculation

Estimate throttle position based on G-Forces. 0-100%

--Developed by Scott Barton of ProFormance Coaching for use by Autosport Labs Community

MaxAccelG = 0.30 -- Look at your logs and see what your max acceleration is in 3rd or 4th gear. Note that full acceleration in 5th will not show 100% throttle.

chThrottle = addChannel("vThrottle", 10, 0, 0, 100,'')

function updatevThrottle()

--AccelG = getChannel(LongAccel) --2.13 Firmware and up

AccelG = getImu(0) --Prior to 2.13 Firmware

TPS = (AccelG/MaxAccelG)*100

if TPS < 0 then TPS = 0 end

TPS = math.abs(TPS)

if TPS > 99 then TPS = 100 end

setChannel(chThrottle, TPS)

end

--10Hz update

setTickRate(10)

function onTick()

updatevThrottle()

end

Brake Position Calculation

Estimate brake pedal position based on G-Forces. 0-100%.

--Developed by Scott Barton of ProFormance Coaching for use by Autosport Labs Community

MaxDecelG = 1.20 --Look at your logs and see what your maximum g-forces under straight line braking is and round down.

chBrake = addChannel("vBrake", 10, 0, 0, 100, '')

function updatevBrake()

--BrakeG = getChannel(LongAccel) -- 2.13 Firmware and up

BrakeG = getImu(0) --Prior to 2.13 Firmware

--if ReverseAccel then

BrakeG = BrakeG *-1

--BrakeG = -1.1

BrakePos = (BrakeG/MaxDecelG)*100

if BrakePos < 10 then BrakePos = 0 end

BrakePos = math.abs(BrakePos)

if BrakePos > 99 then BrakePos=100 end

setChannel(chBrake, BrakePos)

end

--10Hz update

setTickRate(10)

function onTick()

updatevBrake()

end

Max RPM detection with GPIO reset

This script detects the peak RPM detected and stores it in a virtual channel. A GPIO is used to reset the channel to zero via a push button.

maxRpmId = addChannel("MaxRPM", 10)

maxRpm = 0

function rpmReset()

local rpm = getTimerRpm(0)

local clear = getGpio(0)

if rpm > maxRpm then

maxRpm = rpm

setChannel(maxRpmId, maxRpm)

end

if clear == 0 then

maxRpm = 0

setChannel(maxRpmId, maxRpm)

end

end

function onTick()

rpmReset()

end

Alerts/Notifications

Create an over-rev marker

This script will mark the datalog with an over-rev alert marker whenever RPMs are above a certain threshold. It will insert the current lap number to the OverRev channel. If multiple occurrences happen, you can take a look the event summary page and then look at each of those lap to see where and when it happened.

Given:

- RPM is connected a timer channel called RPM

- RPM over-rev condition is 8000

setTickRate(10)

overRevId = addChannel("OverRev", 10)

function onTick()

local rpm = getChannel("RPM")

if rpm ~= nil and rpm > 8000 then

setChannel(overRevId, getLapCount())

end

Create an Impact marker

This script will mark the datalog with an impact occurs (very high G-Forces). It will insert the current lap number to the Impact channel. If multiple occurrences happen, you can take a look the event summary page and then look at each of those lap to see where and when it happened.

setTickRate(10)

impactId = addChannel("Impact", 10)

function onTick()

local gsum = getChannel("Gsum")

if gsum ~= nil and gsum > 2.0 then --Assumes anything over 2.0G's is an impact. Change to suit your needs.

setChannel(impactId, getLapCount())

end

end

Control a Fan or Pump switch based on Temp

function updateDiffSwitch()

local diffTemp = getChannel("DiffTemp") --Change to your temperature channel name

if diffTemp ~=nil and diffTemp > 180 then --update temp to turn on at

setGpio(2,1)

elseif diffTemp ~=nil and diffTemp < 160 then --update temp to turn off at

setGpio(2,0) --Uses GPIO3 for output. Increase SampleRate or TickRate if it isn't turning on

end

end

Alert driver via electro-shock if oil pressure below safe threshold

This will alert driver via a shock (using pet scat mat) if oil pressure drops below threshold while engine is running above certain RPM

Script will check at 10Hz (10 times/sec) for threshold condition

Given:

- Oil pressure on analog channel 0, and calibrated

- Seat mounted pet scat mat installed in seat and controlled by GPIO 0 (GPIO switches ground when active)

- GPIO 0 is configured for output mode

- RPM is connected to timer input 0

--onTick() is called at 10Hz

setTickRate(10)

rpmThreshold = 2000

lowOilPressure = 15

function onTick()

local shockDriver = 0

if getTimerRpm(0) > rpmThreshold and getAnalog(0) < lowOilPressure then

shockDriver = 1

end

setGpio(0, shockDriver)

end

Track Max RPM / Value

This script will track a channel's maximum value and set a new channel with that maximum. Given:

- RPM is connected to the first Timer input channel

setTickRate(10)

maxRpmId = addChannel("MaxRPM", 10)

maxRpm = 0

function onTick()

local rpm = getTimerRpm(0)

if rpm > maxRpm then

maxRpm = rpm

setChannel(maxRpmId, maxRpm)

end

end

Activate a GPIO when start finish line is crossed

This script will pulse one of the GPIO outputs when the start/finish line is detected. First, the onTick rate is set to 10hz, then setGpio() is called with the result of the call to getAtStartFinish()

setTickRate(10)

function onTick()

if getAtStartFinish() == 1 then

setGpio(0, 1)

else

setGpio(0, 0)

end

end

or

setTickRate(10) function onTick() setGpio(0, getAtStartFinish()) end

Temperature Warning Indicator Light

This script will activate an output if an analog input exceeds a threshold. It's assumed a temperature sensor is connected to the Analog input channel 0 and is calibrated.

More information: Installation Guide, Sensor Guide, Operation Guide

function onTick() if getAnalog(0) > 212 then setGpio(0, 1) else setGpio(0, 0) end end

Multi warning light

A script to trigger a warning light if at least one condition occurs. This will activate the output if the engine temperature is greater than 212 or if oil pressure drops below 10.

- Note Actual temperature and pressure sensors must be connected to the appropriate analog inputs and correctly calibrated.

--Analog 0 is engine temp, in degrees F --Analog 1 is oil pressure, in PSI function onTick() if getAnalog(0) > 212 or getAnalog(1) < 10 then setGpio(0, 1) else setGpio(0, 0) end end

Enable an LED if fuel level drops below 10%

- Using PWM/Analog output

only available on RaceCapture/Pro MK1 and MK2

- Fuel sensor is on Analog 0, scaled 0-100%

- LED indicator connected to PWM 0. When fuel level drops below 10%, Analog/PWM output 0 will show 5v; 0v if fuel level is higher

- PWM channel settings are set to factory default

function onTick() local p = 0 if getAnalog(0) < 10 then p = 100 end setPwmDutyCycle(0,p) end

- Using GPIO in output mode

- When fuel level drops below 10%, the GPIO is activated (output is grounded). Can be used to drive a relay or other device up to 1A load

- GPIO jumper set to output mode

- GPIO setting in firmware set to match jumper setting

function onTick() local p = 0 if getAnalog(0) < 10 then p = 1 end setGpio(0, p) end

3 stage Sequential Shift Light

Activates a 3 stage sequential shift light. Also see the Sequential Shift Light project

Given:

- RPM sensor on timer input 0

- GPIO channels are configured in output mode under Setup/GPIO

setTickRate(15) function onTick() local r = getTimerRpm(0) if r > 5000 then setGpio(2,1) else setGpio(2,0) end if r > 6000 then setGpio(1,1) else setGpio(1,0) end if r > 7000 then setGpio(0,1) else setGpio(0,0) end end

ProFormance Meter

Uses ShiftX to show you how much available grip you are using and how much is left. It also creates and updates the ProFormace channel which is an integer from 0-9. Closer to 9 you are the closer you are to max available grip.

Instead of just using GSum, this takes into account that your MaxLatG's will be different than your MaxLongG's and gives you a more accurate representation of what you can do based on whether you are braking, turning, or accelerating.

It also has 2 different models. 1) for an Advanced Driver and 2) for a Pro Driver. This is based on typical friction circles of Advanced Drivers vs Pro Drivers respectively. See the OnTick funtion to change DriverLevel.

It also has an Oversteer Alert feature for ShiftX. Change the YawThreshold value to suit your needs.

setTickRate(25)

sxSetConfig(1)

yawThreshold = 25 --At what yaw rate do you want the oversteer alarm lights to trigger' Check normal max yaw on your Podium.live race summaries to get a better idea of what value you should use

maxGsumId = addChannel("MaxGsum", 25, 2, -2.0, 2.0)

pctGsumMaxId = addChannel("PctMaxGsum", 25, 0, 0, 100)